Popis

Qgrind XL - automatická bruska pro hrubé broušení

The particularly robust and powerful design of the Qgrind XL planar grinding machine allows for maximum material removal with high precision.

The ForceControl function ensures reproducible grinding results with the integrated electronic measuring systems. By selecting and combining different grinding modes, both maximum material removal rates (roughing) and excellent sample surfaces (finishing) are achieved. With the SmartGrind software function, the grinding process can be continuously monitored and made particularly efficient by means of fully automatic determination of dressing intervals. The integration of a cleaning station and the intuitive software interface set new standards in convenience and user-friendliness.

PŘEDNOSTI STROJE

- Robust design and powerful drives for very fast preparation results - also for high sample throughput

- Precise and reproducible results thanks to electronic force measuring system and automatic removal measurement

- Automatic diamond dresser and optional cleaning station

- Intuitive user interface

ADVANCED TECHNOLOGY AND MEASUREMENT SYSTEM

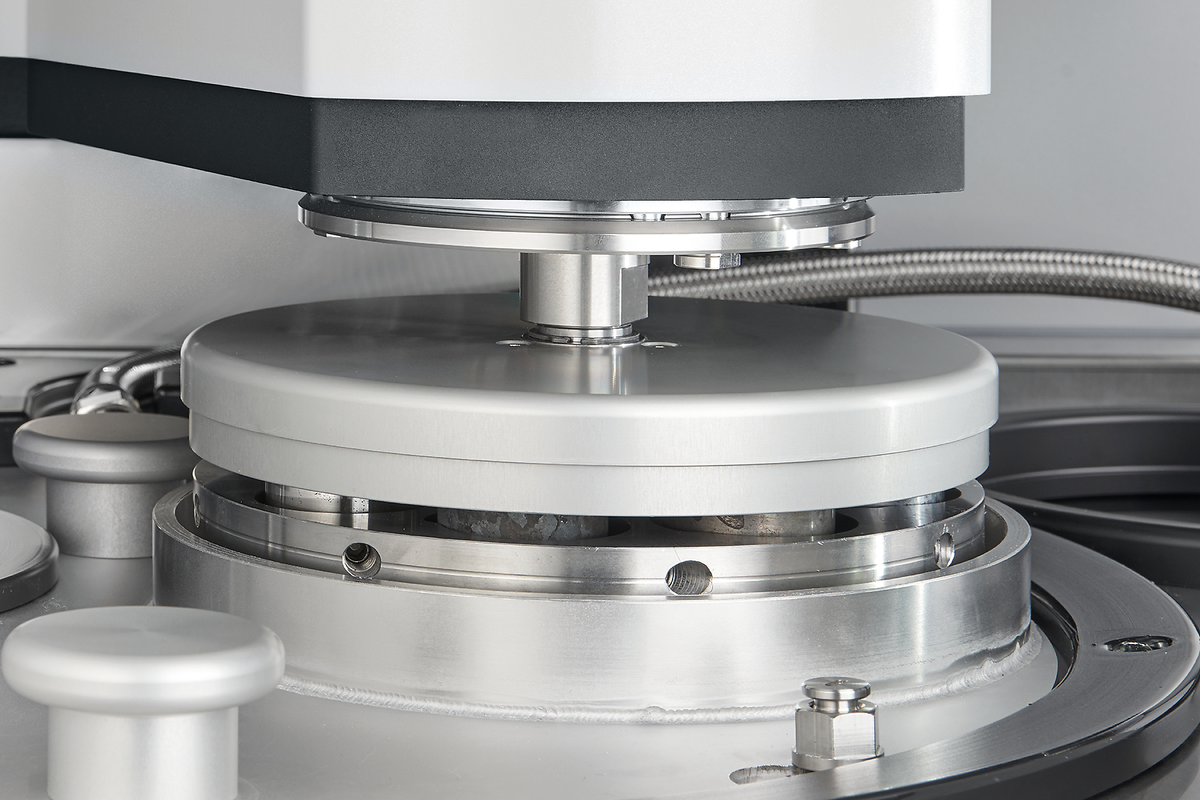

The grinding head and diamond dresser are equipped with a robust ForceControl system and enable reproducible and high grinding forces. The integrated load cells and the innovative motorized force control ensure defined material removal and maximum process reliability.

REPRODUCIBLE PREPARATION RESULTS GUARANTEED

FULLY AUTOMATIC DIAMOND DRESSER

|

In the fully automatic mode (Smartgrind), the grinding process is continuously evaluated and the grinding requirement of the stone is automatically determined and efficiently controlled. Stones may also be dressed at predetermined intervals as well as manually. The remaining stone height, the wear of the dressing diamond and the process flow are shown dynamically on the display. |

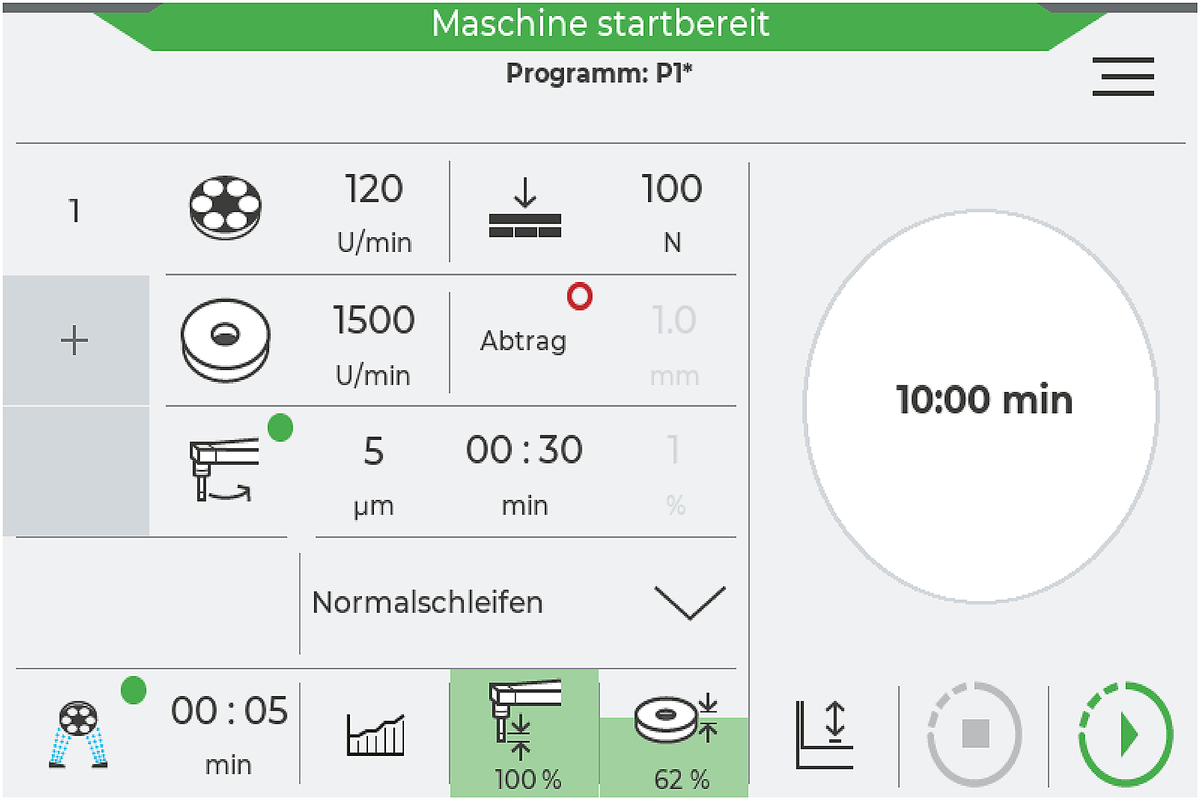

DIFFERENT GRINDING MODES

|

When planar grinding metallographic samples, both high removal rates and flat samples with high surface quality are the goals. In the „roughing“ grinding mode, material removal can be increased by up to 20% compared to conventional processes, thus significantly reducing process times. In „Finishing“ mode the surface quality is improved by up to 15%. The combination of different modes produces optimal grinding results with maximum efficiency. |

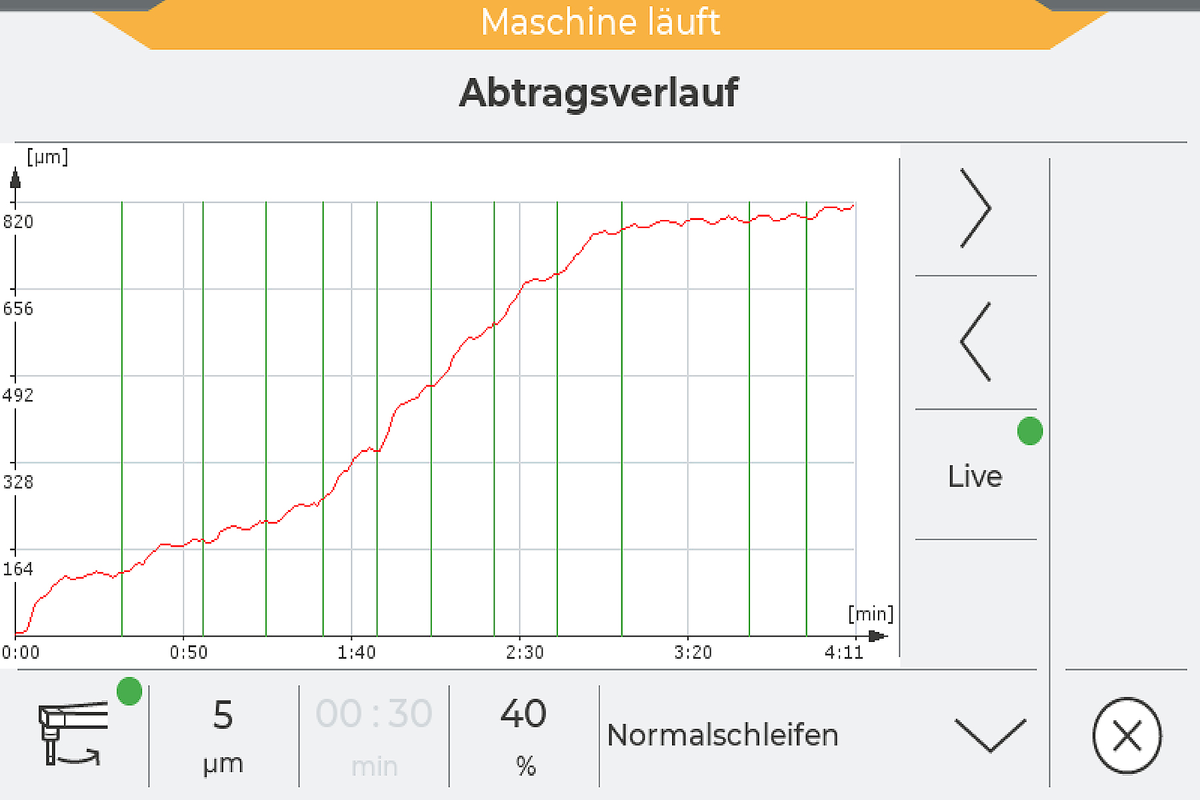

REMOVAL MEASUREMENT

|

The QATM Qgrind XL comes with a system for precise measurement of material removal – regardless of operating time, sample type, material and hardness, you can easily monitor the material height already removed. |

GRINDING STONES AND DIAMOND GRINDING WHEELS

|

High-quality aluminum oxide or silicon carbide grinding stones are available for the various applications. Synthetic resin-bonded diamond grinding wheels can be used for planar grinding ceramic materials and hard metals. The grinding media, specially optimized for materialographic grinding processes, are designed for high removal rates, surface qualities and flatness. The QATM grinding media are approved for rotational speeds of up to 2000 rpm as standard. |

CLEANING STATION (OPTIONAL)

|

In the cleaning station specimens are automatically cleaned with water, ethanol and air and by spin cycling at up to 800 rpm (adjustable). Thus, each preparation step is finalized with a cleaning step. |

PŘÍSLUŠENSTVÍ

|

QATM offers a wide selection of standard sample holders with different diameters and for a variety of applications and machines. Clamping of samples with unusual dimensions can be realized with special sample holders. |

EASY AND QUICK CHANGE OF THE GRINDING STONE

ABSOLUTELY INTUITIVE AND SMART

WELL THOUGHT IN EVERY DETAIL

ROBUST ENGINEERING - FUNCTIONAL DESIGN

|

The basic requirements when developing the automatic grinder Qgrind XL were a corpus and polishing head of utmost stability. These requirements form the basis for a low-vibration and robust grinding process. A solid steel construction, powder-coated and a working area lined with stainless steel emphasize the sustainable, and at the same time modern and compact, machine design – made in Germany. |

CONVINCING PERFORMANCE DATA

|

A 4 kW drive motor drives the grinding stone of the Qgrind XL and ensures high material removal and rotational speeds of up to 2000 rpm. The sample holder is driven in the grinding head with up to 1.1 kW, which means that grinding forces of up to 750 N can be achieved. The speed of both systems can be variably controlled. |

MAXIMUM SAFETY

|

The motorized acryl glass safety hood protects the working area of the machine. The transparent hood is equipped with a safety switch and opens automatically when the program is finished. For easy cleaning the hood can simply be unhinged. |

ŘÍDICÍ SOFTWARE QGRIND XL

POHODLNÝ PROVOZ

|

The modern design of the proven QATM control software enables intuitive and user-friendly operation. All process parameters are clearly displayed and can be easily set by touch. The grinding process is continuously monitored and graphically displayed using the SmartGrind software function.

Funkce

|

|

|

SENSATIONALLY VERSATILE

FEATURES AND EQUIPMENT VARIANTS

COOLING

|

A circulation cooling tank can be seamlessly integrated into the machine base and is easily accessible via push-to-open door. Lateral guidance of the extendible and rollable unit via slide rails. During the grinding process, the flow and temperature of the coolant are monitored in the software. Depending on the application, different circulation cooling systems can be used with the Qgrind XL. |

TOOL COMPARTMENT

|

The tool compartment integrated in the machine housing is particularly practical. This means you always have easy access to all tools. |

MANUAL CLEANING

|

An integrated rinsing hose allows for manual cleaning of the working area. |

SIGNAL LAMP

|

The optional signal lamp allows monitoring of your Qgrind XL from a distance: The red/yellow/green lights show the current state of the machine at a glance. |

PREPARATION FOR EXTERNAL SUCTION

|

Direct suction of vapor from the working area through suction nozzle. |

PARAMETRY:

|

Hmotnost |

~ 433 kg |

|

Application |

Automated planar grinding of materialographic specimens |

|

Fields of application |

Preparation of specimen surfaces for materialographic analysis |

|

Grinding stone |

Ø max. 356 mm |

|

Speed of grinding stone |

variable (1000 - 2000 rpm) |

|

Sample holder |

Ø 160 - 204 mm |

|

Speed of sample holder |

variable (30 - 160 rpm) |

|

Running direction of sample holder |

clockwise/counterclockwise |

|

Pressing system |

central pressing force, electromotive force control |

|

Sample holder pressing force (central) |

50 - 750 N |

|

Removal measurement |

±0.1 mm display accuracy at 1 mm removal |

|

Removal range |

0.1 mm - 10 mm |

|

Drive power grinding stone |

4 kW (S1 operation) |

|

Drive power sample holder |

0.75 kW (S1 operation) |

|

Connection power |

9 kVA |

|

Power supply |

400 V / 50 Hz (3Ph / N / PE), 480 V / 60 Hz (3Ph / N / PE), 220 V / 60 Hz (3Ph / N / PE) |

Brožura QGRIND XL (777.5 kB)

Brožura QGRIND XL (777.5 kB) Brožura z katalogu QGRIND XL (237.6 kB)

Brožura z katalogu QGRIND XL (237.6 kB) Brožura QGRIND XL - příslušenství (671.5 kB)

Brožura QGRIND XL - příslušenství (671.5 kB)

VIDEA:

| Hmotnost | 433 kg |

| Číslo celního sazebníku | 84798997 |

| Země původu | DE |

| Application | Automated planar grinding of materialographic specimens |

| Fields of application | Preparation of specimen surfaces for materialographic analysis |

| Grinding stone | Ø max. 356 mm |

| Speed of grinding stone | variable (1000 - 2000 rpm) |

| Sample holder | Ø 160 - 204 mm |

| Speed of sample holder | variable (30 - 160 rpm) |

| Running direction of sample holder | clockwise/counterclockwise |

| Pressing system | central pressing force, electromotive force control |

| Sample holder pressing force (central) | 50 - 750 N |

| Removal measurement | ±0.1 mm display accuracy at 1 mm removal |

| Removal range | 0.1 mm - 10 mm |

| Drive power grinding stone | 4 kW (S1 operation) |

| Drive power sample holder | 0.75 kW (S1 operation) |

| Connection power | 9 kVA |

| Power supply | 400 V / 50 Hz (3Ph / N / PE), 480 V / 60 Hz (3Ph / N / PE), 220 V / 60 Hz (3Ph / N / PE) |

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.