OPTIC CONTRASTING METHODS

Whether a microstructure is visible under polarized light (with a sensitive tint plate in the optical path) or not, strongly depends on the phases of the analyzed material. In this context the material's Bravais lattice type is of great importance. While BCC and FCC metals like steel, aluminum, copper, or chromium need to be etched to see a microstructure, HCP metals and alloys like α-titanium, cobalt, hafnium, zinc alloys or the orthorhombic bismuth show their microstructure in the polished state.

There are various techniques of optic contrasting. Birefringent crystals, for example, (like spherulites in partially crystalline polymers like polyamides or high-density polyethylene), can be visualized via phase contrast methods. Fluorescence microscopy and dark field microscopy are also important contrasting methods for failure analysis. However, they are usually applied to visualize microcracks, pores, or similar material inhomogeneities.

In many cases however, the incident light from the microscope is reflected quite uniformly. Therefore, contrast must be generated in another way to enable any kind of optical evaluation, e. g. by metallographic etching.

METALLOGRAPHIC MICRO & MACRO ETCHING

The etching of polycrystalline solids is an important part of metallography. Etching can be carried out based on different physical and chemical processes, which help to reveal the micro structure or macro structure of the workpiece. This contrast generation is essential for light microscopic analysis.The choice of the metallographic etching procedure is strongly influenced by the analytical objective of the metallographic process. In general, a distinction is made between metallographic micro-etching and metallographic macro-etching; the first is used to analyze the microstructure of materials at specific points, the latter aims at showing differences in the microstructure across the geometry of parts. Apart from different etching reagents and etching times, the material itself plays an important role for the obtained results.The metallographic preparation before the etching step is also essential. While micro-etching always requires polished surfaces (usually produced by a metallographic polishing machine), a fine-ground sample may be sufficient for macro-etching. In general, metallographic etching can be based on physical mechanisms (thermal etching), electrochemical reactions (electrolytic etching), or spontaneous redox reactions (chemical etching).It needs to be clarified whether mounted samples previously processed by a hot mounting press can be used or whether samples without mounting material yield better results. This sometimes is the case if a material is electrolytically polished and etched. Electric conductivity, thermal shock and high temperature behavior of the material must be taken into consideration for thermal or electrolytic etching as well. The individual processes are exemplary discussed below.

|

COMPARISON OF METALLOGRAPHIC ETCHING PROCESSES

|

|

|

Thermal etching

|

Chemical etching

|

Electrolytical etching

|

|

Devices

|

Tube/muffle furnaces with temperature control, crucible tongs, inert gases (N2, Ar)

|

Etching trays, crucible tongs, heating plates, other standard accessories of a wet-chemical laboratory

|

Electrolytic etching device

|

|

Consumable materials

|

Cleaning media (alcohols/water, etc.)

|

Etching media, cotton wool, cleaning media (alcohols/water, etc.)

|

Electrolytes, cotton wool, cleaning media (alcohols/water, etc.)

|

|

Materials

|

Oxide ceramics, carbide ceramics, cobalt-based alloys, nitride ceramics, titanium, steel

|

Ferrous materials, non-ferrous metals, oxide/carbide/nitride ceramics, rock, nickel, aluminium and other main group metals/alloys, titanium and other secondary group metals, semiconductor materials

|

Metals that appear in the electrolytic series of voltage. It is often used in the field of aluminium alloys, iron and copper materials

|

|

Temperature

|

Most important method parameter lies below the sintering temperature

|

RT and temperatures up to the boiling point of etching medium (generally < 300 °C)

|

RT to slightly elevated temperatures (< 100 °C)

|

|

Time expenditure/process

|

10 - 60 min

|

Few seconds to 30 minutes

|

1 - 30 min

|

|

Handling

|

Challenging (temperature control)

|

Simple to challenging (complex geometries, metals susceptible to corrosion)

|

Simple to very complex (method development)

|

|

PPE/workplace equipment

|

Active extraction unit, thermal protection, gloves, apron, visor

|

Fume cupboard, protective clothing, protective gloves, protective goggles

|

|

|

|

Detailed requirements depend on the furnace volume and target temperature

|

Detailed requirements depend on the chemical properties of the media used

|

|

|

Reproducibility

|

Good to a limited extent

|

Good to a limited extent

|

Good

|

|

Costs

|

High investment costs / low follow-up costs

|

Low investment costs / medium follow-up costs

|

High investment costs / medium follow-up costs

|

Chemical etching is the most common type of metallographic etching. It is popular due to its high cost-efficiency and simple technique. In most cases, etching is done by immersion. The sample surface to be etched is completely immersed in the etching medium and moved around. Swab-etching also occurs in some applications. Here, cotton pads or very soft tissues are wettened with etchant and the sample surface is wiped. This method is usually applied, when immersion etching is technically not possible due to the susceptibility of the sample to etching. Care must be taken to not scratch the prepared surface. In most cases, chemical etching is a selective corrosion or oxidation. This is called structure etching.

In the case of oxidative etching, a redox reaction takes place between a component of the etching medium, often H+/H2 and the solid, which often is metallic. This reaction occurs with a higher reaction velocity depending on crystallographic orientation (with grain surface etching) and crystal distortion (with grain boundary etching). The chemical composition of the phases also leads to different electrochemical potentials and thus different oxidation rates. This causes a relief formation, which becomes microscopically visible as shading contrasts.

With some systems, e. g. the "Kalling 2" reagent, reduced metals or salts are deposited on the etched sample. These can be removed using cotton wool. Only then the etched microstructure becomes visible. The informative value of a pure structure etching is limited because the mentioned etching mechanisms overlap, and not much information regarding the grain orientation is accessible. The primary goal of structure etching is related to the determination of grain size distribution and phase composition of certain materials.

This makes the development of microscopic methods like the automated determination of grain orientations almost impossible. The same applies, to a certain degree, to chemical inhomogeneities. It should be noted that non-metallic inclusions can be reliably represented with pure structural etching.

This can be well illustrated using the example of a low-alloy steel. The ferrite has a lower chemical potential than precipitated cementite or graphite, which leads to a faster oxidation of the phase. Distorted grain boundaries are removed more slowly, and they form protruding areas in this case. Due to the lamellar structure of the pearlite, this phase results in a homogeneous relief etching in the grain, which can be recognized by dark grey stripes. Depending on the orientation of the grain to the grinding plane, these stripes are more or less clearly visible. In this case, Nital or V2A etchant would be a typical structure etching reagent

With different metallographic etchants, so-called color or precipitation etching is possible. This etching technique provides more microstructural information and is much more difficult to perform in a repeatable way.

Besides the phase- and orientation-selective attack of the etching medium, a layer belonging to the redox system is deposited. This layer is of different thickness, depending on the local reaction velocity. This leads to interference phenomena of the incident light, which manifests itself in a strongly orientation-dependent discoloration of the grain surfaces, which becomes visible under polarized light. In the case of metallographic over-etching, the interference disappears due to an excessive layer thickness.

A well-known color etching applied on low-alloy steels is the color etching according to Klemm. Different color etching reagents based on the anodic formation of sulfide films are applied for steel. The etching reagents according to Behara and LePera, differ in additives and the sulfite carriers used. The different reagents are chosen depending on the specific alloy system to be analyzed.

Color etching processes are also very common in inorganic-nonmetallic applications, e. g. for cement clinkers. The mechanisms of many color etching processes have not yet been fully understood. However, they often work reliably when quantifying phases.

|

|

|

|

|

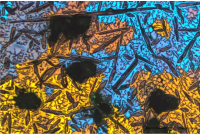

AlFe10, Fcc Aluminium

matrix with needles of

FeAl3, etched

electrolytically with

Barkers' reagent

|

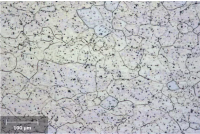

AlMg 4.5 etched

with 7% NaOH

solution

|

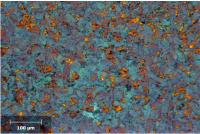

Austenitic V2A steel,

etched with

Beraha 2 etchant

|

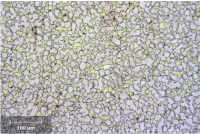

Alpha and beta brass, etched with

10% aqueous

ferrinitrate

|

For chemical etching, the following important parameters must be considered after selecting the basic metallographic etching method:

-

Concentration of the used etching solution: Most chemical etching solutions are aqueous or alcoholic mixtures. They can usually be diluted as desired. This is especially recommended for very base metals to extend etching times and to prevent over-etching of samples. In case of very corrosion-resistant materials, a restriction of the etching medium can lead to better results.

-

Etching time: This parameter must be determined individually for a sample type. It has the most important influence on the metallographic etching result. Excessively high etching times lead to over-etching (usually recognizable by indefinable coatings and strong discoloration of the sample surface) while excessively short etching times result in an incomplete representation of the microstructure (poorly visible grain boundaries,

very low discoloration of grain surfaces, etc.)

- Age of etching solution: This is a common reason for faulty results,especially in case of color etching. For this reason, many color etching reagents should be freshly prepared each working day or week to obtain optimum results. Structure etching solutions are usually stable over a longer period of time. The etching solution can be used multiple times. In most cases, color changes or precipitation failure are sure signs that thesolution is too old.

-

Temperature of the etching medium: Usually high temperatures accelerate metallographic etching processes, whereas low temperatures slow them down. To ensure good reproducibility, metallographic etching should be performed at constant temperatures. Variations in the range of a few °C are usually negligible. Very corrosion-resistant materials often need to be etched at elevated temperatures.

- Cleaning the sample after etching: The sample must be cleaned immediately after metallographic etching to prevent over-etching of the sample. In mostcases, rinsing is done first with water, then with ethanol. Mounted samples are often "tapped" to remove the etching reagent that has penetrated the gap to the maximum possible extent. Especially with very base metals, e. g. Mg- or Zn-alloys, only alcohols should be used, since water is an oxidizing agent for these materials. The samples are dried directlyafter cleaning to prevent the formation of dry spots. The use of aggressive detergents and surfactant mixtures is not recommended in any case.

Like chemical etching, electrolytic etching is based on the formation of numerous galvanic elements on the polished sample's surface. In this case, it isnecessary to apply an external voltage to the sample to force the desired redox reaction.

In addition to the factors listed above, locally varying electrical conductivity and the set voltage or current of the electrolysis cell influence the removal rate. When an automatic metallographic etching machine is used, flow rates and etching cell geometry also have an impact on the displayed microstructure. Electrolytic methods usually show higher removal rates than chemical etching, which is why they can be used as metallographic polishing processes, too. This is the greatest advantage of the process, since the replacement of metallographic polishing steps makes it possible to produce completely deformation-free sample surfaces and reveal the true microstructure, which is not possible with other metallographic etching processes.

The transition between electrolytic polishing and electrolytic etching is mainly determined by the applied current density. Electrolytic etching is used almost exclusively in the field of metallography. Since it is an automatically controlled process, it offers a higher reproducibility than purely chemical etching processes. These are still performed manually and require a higher level of user experience. Metallographic electrolytic etching can also be described as anodizing a metal. Generally, more noble, or at least equivalent, metals are connected as cathodes, while the sample serves as the anode.

|