|

After metallographic sectioning the sampled material is usually encapsulated with a plastic shell. This process step is called metallographic mounting. It results in the classic sample ready for metallographic grinding and polishing. In many cases, mounting leads to a simplified sample preparation and thus to better results.

QATM is a leading manufacturer and supplier of high-quality consumables for mounting as well as a range of innovative machines for hot and cold mounting, from hot mounting presses to UV mounting devices. The QATM application experts combine decades of experience with thousands of processed samples and will be happy to assist with your application.

|

QATM offers metallographic mounting devices for any requirement

|

ADVANTAGES OF METALLOGRAPHIC MOUNTING

- Unwieldy samples with small or complicated dimensions are fixed in cylindrical solids that can be easily handled. Often mandatory for semi-automatic metallographic grinding and polishing with standardized sample holders

- Sensitive sample material, e. g. soft, brittle, fragile, porous solids, is protected during the metallographic grinding process. Better edge retention protects coatings and marginalized layers as well

- Several samples can be combined in one solid

- Preservation of marginalized layers and coatings, as in the case of nitrided steels, plasma-sprayed coatings, or paint layers.

- Improves further processing with semi or fully automatic metallographic grinding and polishing devices, guidance in sample holders, consistent size, i. e. the sample diameter is adjusted.

METALLOGRAPHIC COLD AND HOT MOUNTING

Basically, a distinction is made between hot and cold metallographic mounting, depending on whether heat is required for the polymerization process during mounting. It must be noted that during cold mounting polymerization temperatures of up to 130 °C may arise when using, e. g., methyl acrylates. Today, the term cold mounting is generally used for all metallographic mounting methods where no or small pressures (<5 bar) are applied.

When it comes to the selection of metallographic mounting methods, arguments for or against a certain method can be found. The below overview presents the process differences between metallographic hot and cold mounting.

COMPARISON OF HOT AND COLD MOUNTING

|

Feature

|

Metallographic Hot Mounting

|

Metallographic Cold Mounting

|

| Devices |

Hot mounting press |

Take-off the pressure device if necessary, infiltration set

|

| Plastic types |

Phenolic resin, Acrylic resin, Epoxy resin |

Methyl methacrylate, Polyester resin, Epoxy resin

|

| Time expenditure per process |

10 - 15 min |

5 minutes – 12 h (depending on the plastic types)

|

| Handling |

Simple, granulate/powder is filled in the mold assembly |

Observe dosage (volume or weight %), mixing of 2-3 components

|

| Flexibility in terms of shape selection |

Limited, significant additional costs |

Large, with low cost

|

| Result |

Plane-parallel specimens, depending on the type of granules, hardness, low gap and transparency can be achieved |

No plane-parallel specimens, depending on the plastic selection, hardness, low gap and transparency can be achieved

|

| Cost expenditure for plastic/granulate |

Costs are considerably lower |

Costs are considerably higher

|

| Occupational safety |

Observe safety data sheets. Use extraction unit |

Observe safety data sheets. Use take-off unit

|

REQUIREMENTS FOR METALLOGRAPHIC MOUNTING COMPOUNDS

|

Metallographic hot and cold mounting are not in direct competition, but there is a certain overlap in application ranges.The most important criteria for metallographic mounting compounds are hardness, abrasion resistance, shrinkage, and chemical resistance.

Low shrinkage during solidification and good adhesion to the sample are important. Without these, a gap will form between the sample and the mounting material. This causes edge rounding, accumulation, and carryover of grinding and polishing media or the rupture of surface coatings. |

|

|

The following points need to be observed as well:

- Bubble-free condition – ground air bubbles act as pores and promote the carryover of grinding and polishing media

- Correct viscosity during casting. All irregularities in the sample such as cracks, shrink holes or pores must be filled.

- Identical metallographic grinding or polishing behaviour as the mounted material. Soft materials should be mounted in soft mounting media and hard materialsin hard mounting media

- Inert behaviour of the mounting material during metallographic sample preparation and analysis

- No reaction with the sample

- The material must not be changed by high temperatures or pressure during metallographic mounting; undesirable deformations and transformations could be the result

- If necessary, good electrical conductivity for further processingi n metallographic electropolishing or electron microscopic applications

|

Metallographic hot mounting compounds

|

Metallographic cold mounting

compounds

|

|

Powder, granules or preforms are compacted under pressure and heat in an mounting press

|

Liquid and/or powder is mixed with hardener and poured into embedding molds

|

|

Raw material can be stored for as long as required

|

Raw material must be stored in a cool place and has a limited shelf life

|

|

Mounting time for one sample is 10 to 18 minutes, a maximum of two samples per mounting cylinder

|

Curing time for one sample is 15 minutes to 12 hours. Several samples can be mounted simultaneously

|

|

Duroplast: Phenolic resin (bakelite), epoxy resin, diallylphtalate

|

Duroplast: Epoxy resin, polyester resin

|

|

Polymerised to a mass that cannot be softened further

|

Polymerised to a mass that cannot be softened further

|

|

Heating up to approximately 150-200 °C under pressure (200 bar)

|

Pay attention to temperature increase during polymerization. This depends on the mixing ratio, the external temperatures, the quantity of components used and the heat dissipation of the embedding molds

|

| Thermoplastics: Acrylates |

Thermoplastics: Acrylates

|

| Can be softened again, heating without pressure, cooling under pressure |

Can be softened again, temperature increase 50-120 °C, short hardening time

|

|

|

|

|

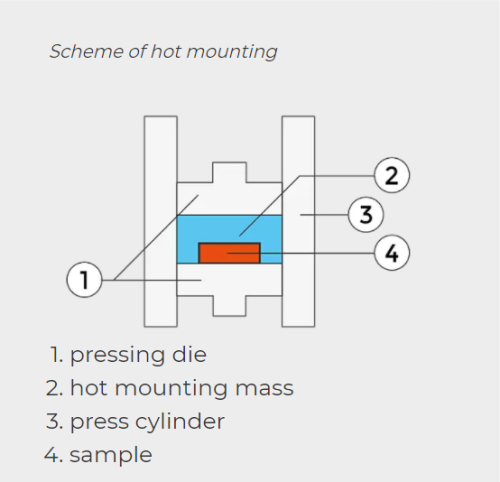

METALLOGRAPHIC HOT MOUNTING

Hot mounting could also be called hot biaxial pressing. It is a process in which a granulated polymeric material is softened, compressed, and cooled down sequentially. The process is carried out in a metallographic hot mounting press, designed for this application. Of course, this method may only be applied on sufficiently pressure- and temperature-resistant samples with simple geometries. The process is carried out at temperatures of 150 to 200°C, while the pressure depends on the mold diameter and ranges from 100 to 300 bar. After placing the sample on the lower ram, the mounting material is added and the metallographic mounting process is started.

|

|

|

Two types of materials are used for metallographic hot mounting:

- Hot mounting materials may be thermosets, like phenolic resins with differing fillers, diallylphthalates, melamine and epoxy resins with mineral fillers, or thermoplastics. Thermosets cross-link at high temperatures and can not be molten afterwards.

- Most thermoplastics used in metallographic hot mounting are PMMA powders, which form transparent solids after curing. They melt at high temperatures and only start to gain hardness during the cooling process.

In principle, mounted samples may be removed from the metallographic mounting press at elevated temperatures. This, however, has negative effects on material shrinkage, plane-parallelism, and roundness of the cylindric sample. Optimum results are obtained if the sample is cooled under pressure until room temperature is reached. |

|

|

METALLOGRAPHIC HOT MOUNTING MATERIALS AND THEIR PROPERTIES

|

PROPERTY

|

DUROPLAST

|

THERMOPLASTIC

|

| |

Phenolic resin

|

Diallylphtalate

|

Epoxy resin

|

|

|

Filling material

|

Medium |

Copper, graphite |

Glass |

Glass, mineral material |

None |

|

Hardness

|

Medium |

Medium |

High |

Very high |

Low |

|

Gap formation

|

Existent |

Existent |

Very low in gaps |

Very low in gaps |

Existent |

|

Grindability

|

Good |

Good |

Very good |

Very good (not for grinding stones)

|

Satisfactory |

|

Chemical resistance

|

Good |

Good |

Good |

Good |

Satisfactory |

|

Electrical conductivity

|

None |

Good to very good |

None |

None |

None |

|

Product

|

Bakelite black, red, green

|

Duroplast black |

Duroplast blue |

EPO black, EPO max |

Thermoplastic |

|

Thermosets are usually cured between 150°C and 180°C, while the processing window of thermoplastics is slightly bigger. Because they are hardened during the cooling process, their cooling times, depending on the mold diameter, are longer than those of thermosets. In this case, the cooling rate, which is usually lower, must be considered.

Therefore, metallographic hot mounting presses have pulsed cooling modes, which contribute to the release of the plastics’ internal stresses during curing. This prevents crack formation and guarantees a clear sample.

|

PARAMETERS

|

DUROPLAST

|

THERMOPLASTIC

|

|

Polymerization range

|

150-190°C |

130-195°C |

|

Holding time

|

5-8 min* |

5-8 min* |

|

Cooling time

|

3-6 min* |

7-10 min* |

|

Pressure

|

150-180 bar* |

160-190 bar* |

|

* Depending on the diameter of the mold assembly; the greater the mold diameter, the more pressure and time is needed.

|

|

Due to the required process parameters, hot mounting of metallographic samples is a limited application. These limitations apply to electronic assemblies (solders/composites) or pressure-sensitive materials, such as wires or sheets with small cross-sections. In modern metallographic mounting presses, this fact is taken into account by shifting the pressure onset to the point where the target temperature is reached. This extends the application range of the process, but complex network structures or porous rock cannot be hot mounted.

The plane-parallelism of the samples and the easy handling of the metallographic mounting process are of advantage, especially in hardness testing.

It is possible to use several mounting compounds in layers. This allows the specimen to be mounted in hard mounting medium. Afterwards, a cheaper filling material is used, which is covered by a transparent hot mounting material to enclose a sample identification.

Four samples mounted using different compounds

METALLOGRAPHIC COLD MOUNTING

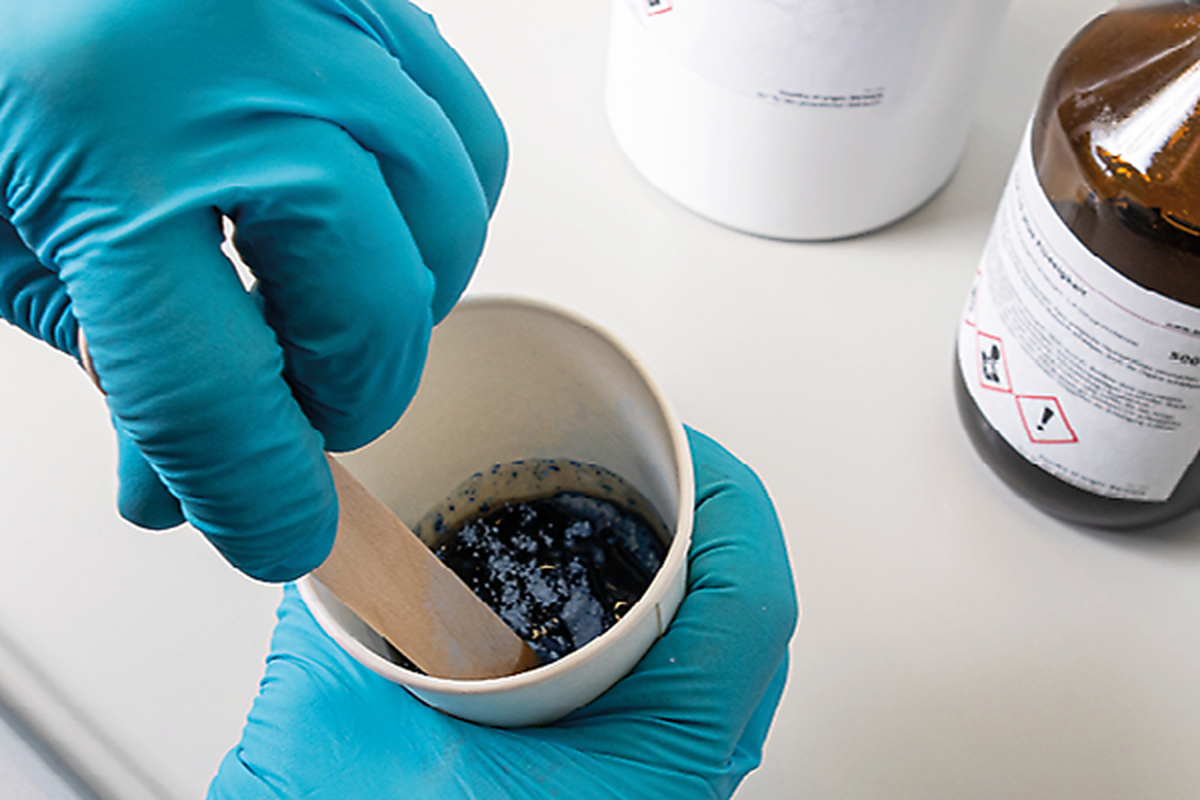

The technical requirements of cold mounting are negligible compared to the metallographic hot mounting process. Only a mounting mold and the cold mounting material are required. Besides hardness and abrasion resistance, shrinkage, curing (pot life), and exothermic heat development are the main selection criteria. The metallographic cold mounting process is carried out as follows:

The sample is placed in a mold and the exact weight or volume proportions of the mounting components are carefully measured. These are then thoroughly mixed (left image) and poured into the mounting mold over the sample (right image). Small samples should be fixed in place before the casting process.

|

|

|

Mixing of cold mounting compounds

|

Pouring of cold mounting compounds

|

Four classes of metallographic cold mounting materials are available:

Acrylic resins are easy-to-use synthetic resins with short curing time. The shrinkage is negligible, especially in mineral-filled systems. They consist of self-polymerizing components that cure by adding a catalyst. After curing, the resin has thermoplastic properties and is chemically resistant. Inorganic fillers are often used to ensure better grindability and hardness. A characteristic feature is the application of the "hardener" component to a powdery solid. These are usually fine PMMA beads with functionalized surfaces.

Like acrylic resins, polyester resins belong to the catalytic polymerizing systems. The curing time is relatively short, and the cured material is duroplastic. Polyester resins tend to show an exothermic effect between acrylics and epoxy resins and a low reaction shrinkage. Their chemical resistance is lower than that of epoxy resins.

Epoxy resins have the lowest shrinkage of all cold mounting resins. Another advantage is their excellent adhesion to almost all materials, which sometimes leads to difficulties when removing the cured sample from its mold. However, a rather long curing time must be taken into account. Another feature is the lower heat development compared to acrylate-based mounting compounds. The polymerization starts as soon as the components are brought together. The cured epoxy resin has duroplastic properties and is insensitive to moderate heat exposure (90-100 °C) and chemical attack. It is the only cold mounting material which allows vacuum impregnation and can be mixed with fluorescent dyes like uranin. This makes them well suited for fluorescence microscopy and enables the contrasting of cracks, pores, and other irregularities in a material. Filled epoxy resins are not available on the market, which limits their applicability in combination with very hard materials.

- Light curing mounting materials

Light curing mounting materials are usually based on acrylates as well. Very few epoxy-based systems, that may be used for this purpose, are available on the market. All of these compounds are ready-to-use, single component solutions. These cure if they are irradiated with blue light or UV-radiation. The application of these materials in metallography is a quite recent development. Therefore, semiautomatic curing ovens have been developed which are used for curing the mounting material. Furthermore, UV-transparent molds, e.g., based on certain glasses, need to be used. Common curing temperatures range between 90 and 120°C and can be influenced by irradiance and irradiation time. Curing times of 1 to 15 minutes are common. The main drawbacks of such one-component mounting materials are their comparably large shrinkage, and high removal rates. These are related to the absence of a hard, inert filler. The resin consists solely of polymeric precursors and initiator. Furthermore, the curing in shaded areas or pores is irregular and limited. To reach a proper curing in spite of these drawbacks, thermal hardener systems are added. Of course, this makes a further tempering (e. g. at 60°C) necessary.

|

|

SELECTION OF COLD MOUNTING MOLDS

The molds used for metallographic cold mounting are reusable. Here only the most commonly used molds are described. Various constructions, for example based on polymer-coated metal parts or different plastics, may be observed in laboratory practice.

- Polyolefin based molds (PE and PP)

In case of older molds, the removable base is often no longer flat. If several small parts are embedded in one sample, different grinding planes can be created depending on the position of the individual sample.

- Teflon (PTFE) based molds

Due to their high dimensional accuracy, ideally suited for automatic grinding and polishing, expensive.

- Silicone rubber-based molds

After repeated use, silicone molds lose their roundness, which can be a disadvantage for automatic preparation in single pressure. When polyester resins are used, sticky spots may arise as a reaction between the mounting compound and the silicone mold. These molds are also suitable for the hardening of UV-initiated cold mounting compounds.

|

Cold mounting molds

|

COMPARISON METALLOGRAPHIC COLD MOUNTING MOLDS

|

|

Method

|

Mounting material

|

Mounting mold

|

| |

|

PTFE opaque

|

PP transparent

|

PE transparent/opaque

|

Silicone opaque

|

| Cold mounting |

Methacrylate,

polyester

|

+++ |

++ |

+ |

++ |

| |

Epoxy resin

|

++ |

++ |

++ |

++ |

| |

Methacrylate

|

+++ |

++ |

++ |

++ |

| |

Modified methacrylate

|

- |

+++ |

++ |

- |

SPECIAL METHODS OF METALLOGRAPHIC COLD MOUNTING

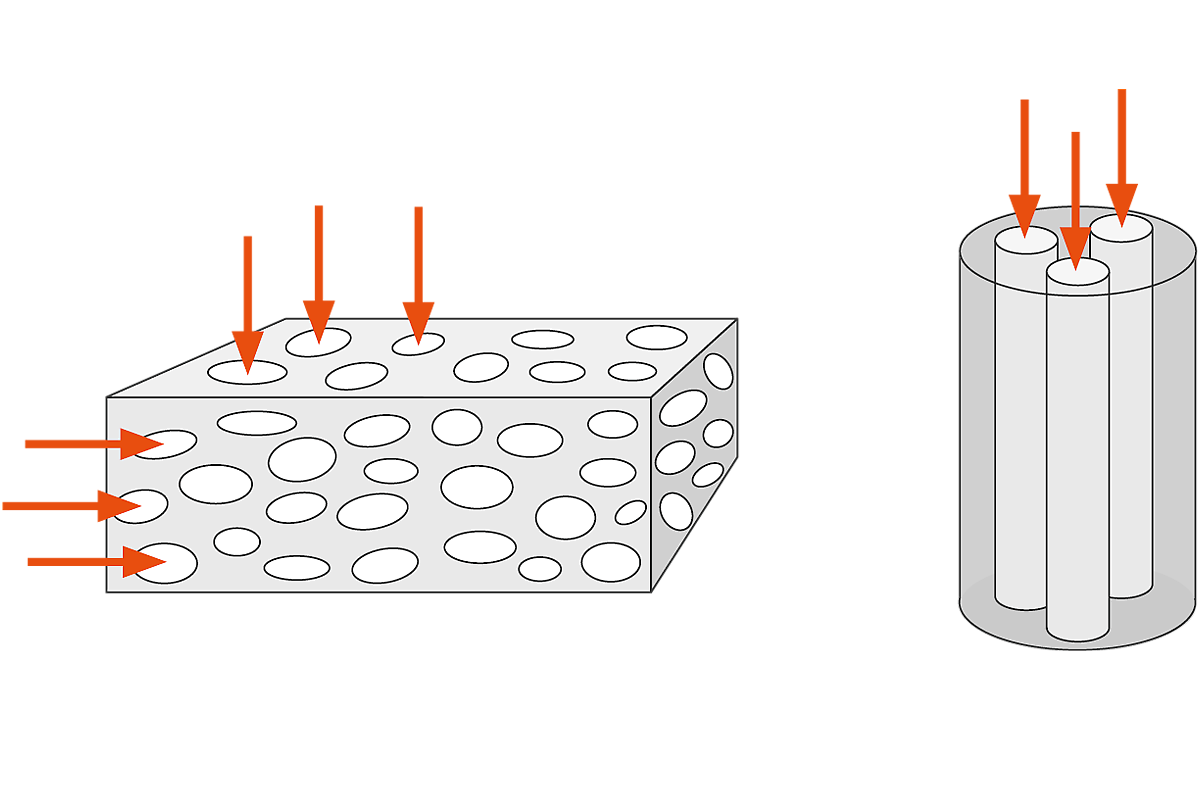

Vacuum Impregnation

Porous materials such as ceramics, sintered materials or spray coatings mustbe mounted under vacuum. Only then can all open pores connected to the surface be filled with the mounting material. This is possible with epoxy resins since vapor pressure and viscosity are sufficiently low. Nevertheless, the vacuum must be limited to pressures below 0.8 bar, otherwise the low-boiling components of the epoxy system will release gas or start to boil.

This process can be used to reinforce and protect sensitive materials. Unwanted preparation effects such as breakouts, cracks and excessiveporosity are reduced to a minimum. However, this only applies to mainly open-pored materials; others, like rather densely sintered ceramics, cannot be properly infiltrated. Damage due to reaction heat or pressure is not to be expected – another reason why there is no alternative to this procedure for porous materials.

Infiltration of porous material or thin holes

Vacuum impregnation is used for infiltration of porous sample material and for optimum metallographic mounting of samples with thin holes, fine pores or micro cracks.

Application of overpressure

Metallographic cold mounting under pressure only makes sense when using acrylates. A simple pressure device is required (compressed air connection 5-6 bar). Better transparency is achieved with unfilled methacrylates. The applied overpressure of 2 to 2.5 bar increases the boiling point of the metallographic mounting compound and suppresses the formation of gas bubbles during polymerization. This enables crystal-clear embedded samples. Pressure cannot replace vacuum as the gas volume cannot completely escape from the pore volume. Therefore, open pores remain partially unfilled and cause the formation of preparation artefacts.

HOW TO AVOID MARGINAL GAPS

Despite the high quality of the metallographic mounting compound used, the formation of marginal gaps cannot always be avoided and occurs especially during cold mounting. This is often due to inadequate metallographic preparation of the sample or its geometry. To avoid the formation of marginal gaps between sample material and mounting material, various parameters must be observed:

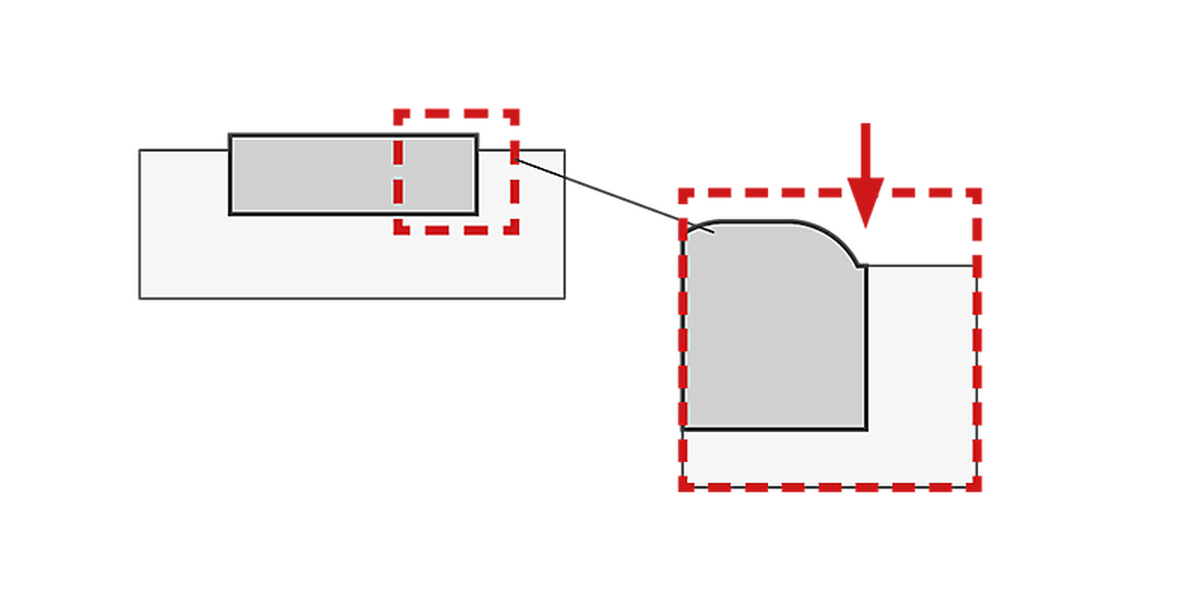

- Sample geometry

Simple rectangular cross-sections are unproblematic. Dovetail connections or drill holes place high demands on the metallographic mounting compound.Especially with inner radii, a non-existent and/or negative shrinkage wouldbe required to mount with minimal gaps.

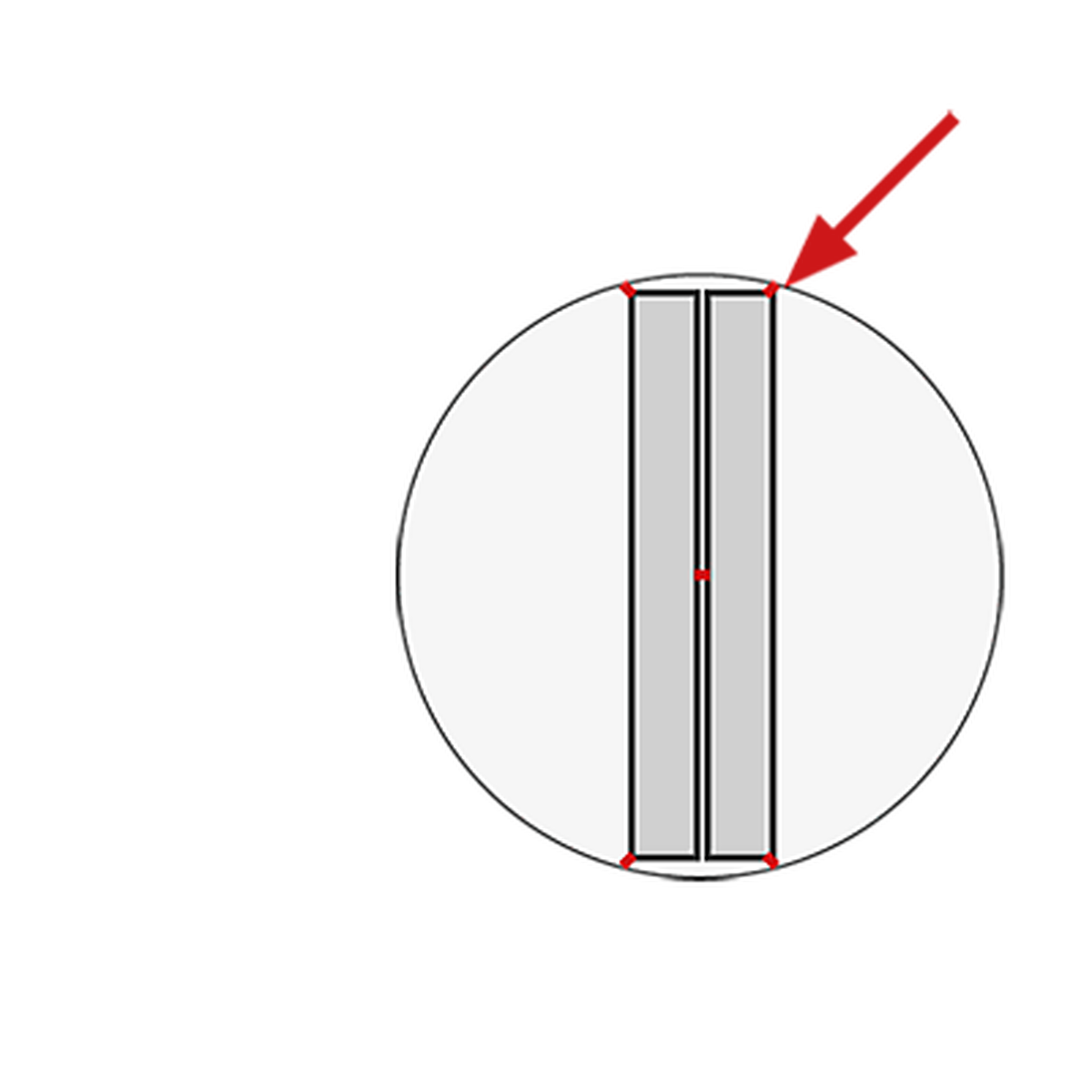

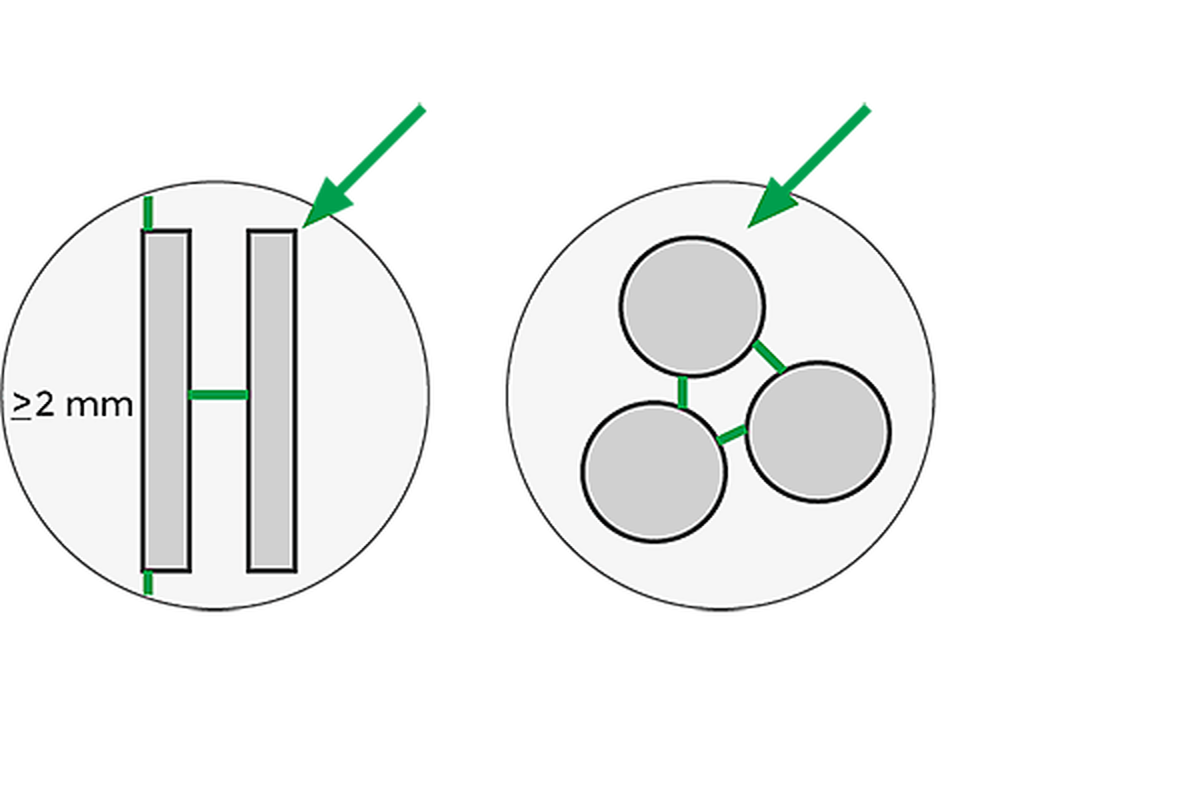

- Arrangement of samples in the mounting mold

Very little distance between the individual samples or to the edge of the mold can cause gaps to form and promote crack formation (approximately2-3 mm distance should be maintained). Breakouts can occur especially at the edge of the specimen which complicates the preparation and may lead to artefacts.

|

|

| incorrect |

optimum |

- Cleanliness of the sample

- Thermal conductivity of the sample material

The risk of gap formation increases the faster the mounting material is cooled down (special caution with methacrylates!).

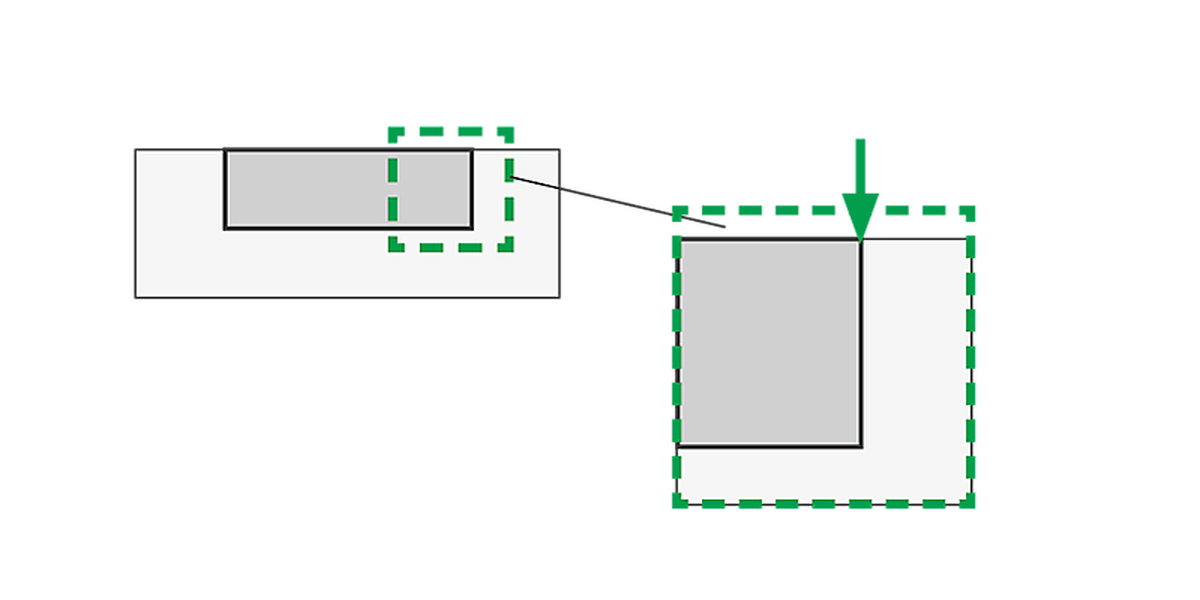

- Hardness of sample and mounting material

For a sharp-edged preparation and protected boundary areas, it is crucial to observe the correct hardness of the metallographic mounting material. In general, a mounting material should be as hard and impact-resistant as possible to achieve a metal-like removal behavior. For this reason, high-filled systems are always used when transparency of the mounting material is not required. This reduces the shrinkage of the material.

|

|

Different hardness for sample and mounting material.

Poor transition of mounting material to sample |

Identical hardness of sample and mounting material.

Ideal transition of mounting material to sample |

The gaps between sample and metallographic mounting material should be as small as possible. Marginal gaps and edge rounding bear the risk of carrying over dirt and grinding or polishing particles. This leads to a deterioration of the metallographic preparation result. Leaking etchant or cleaning alcohol can then falsify the sample micrographs due to after-etching or discoloration in areas close to the gaps.

Shrinkage gap - poor transition of mounting material to sample

|

|

|