Popis

| Hmotnost | 55 kg |

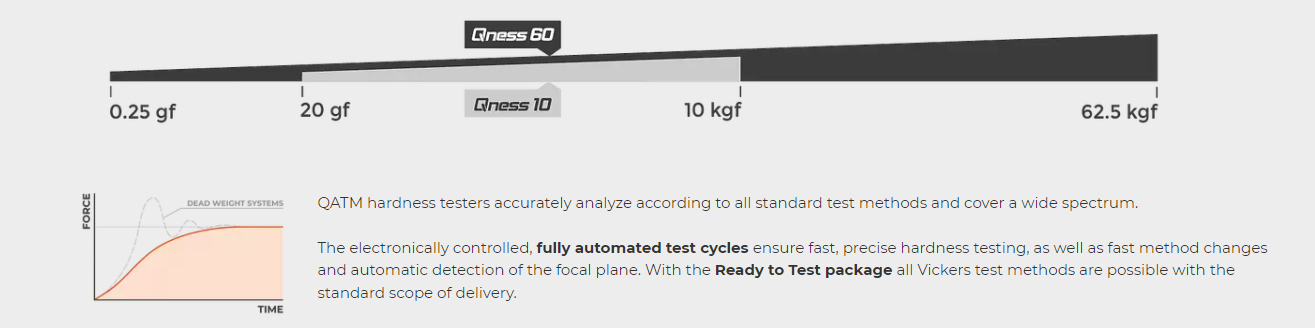

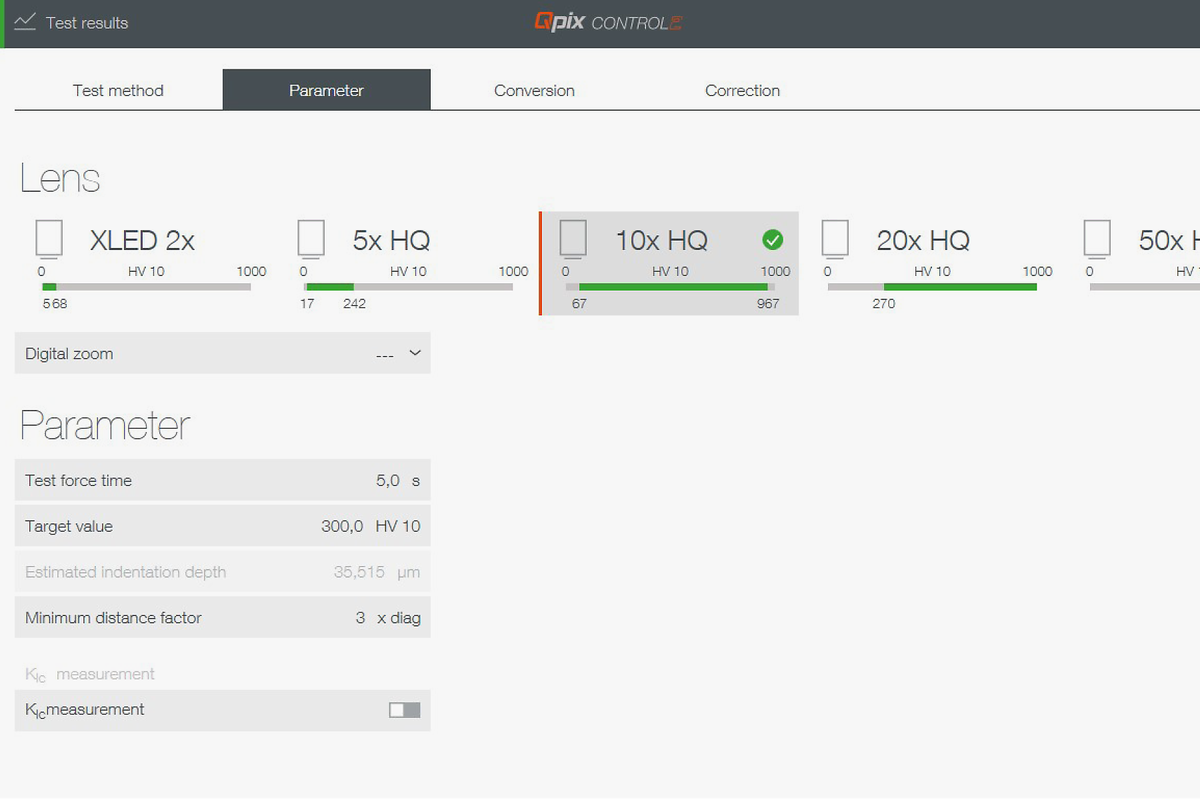

| Test force range | Qness 10 A+: 20 gf - 10 kgf (0.196 - 98.07 N) Qness 60 A+: 0.25 gf - 62.5 kgf (0.00245 - 612.92 N) |

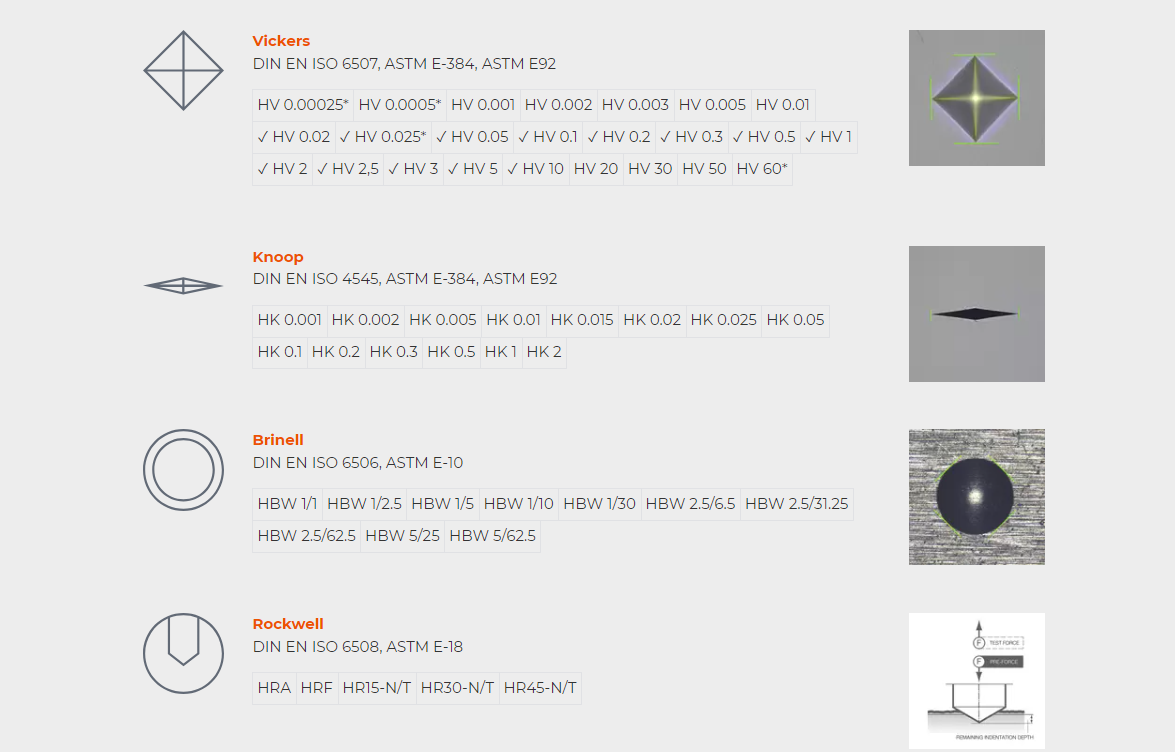

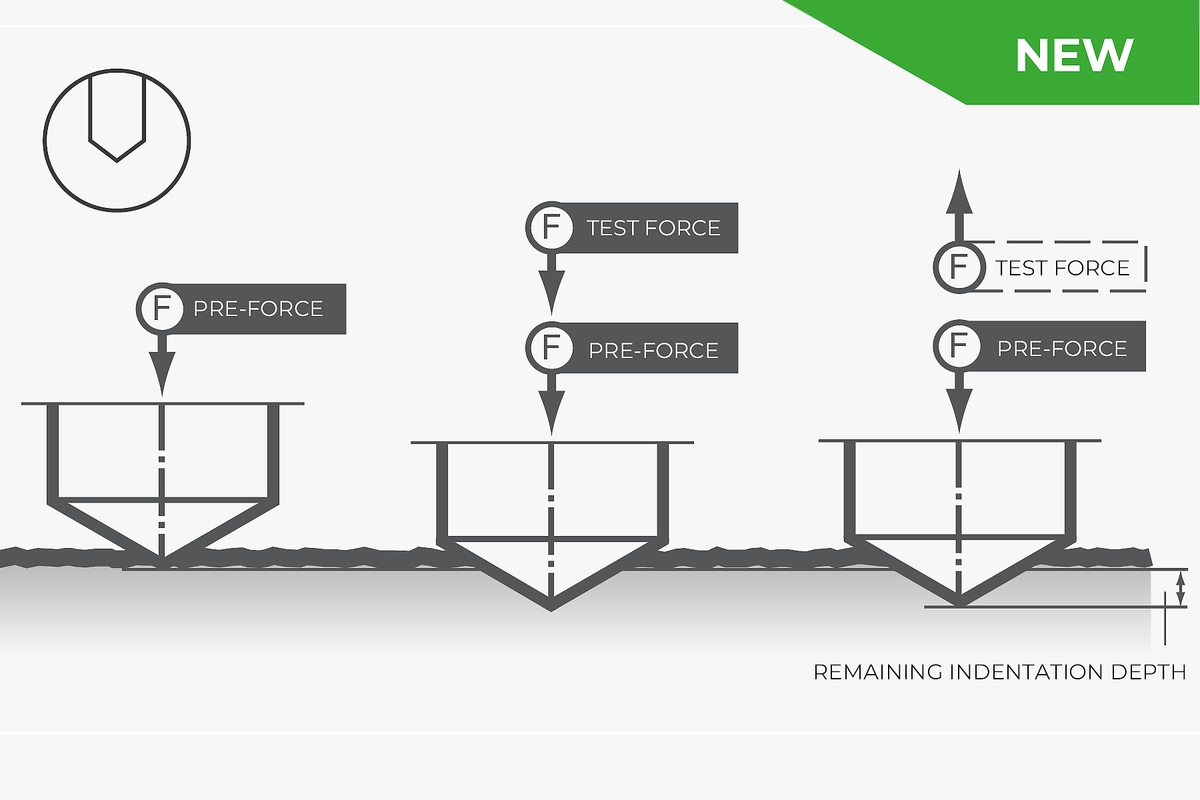

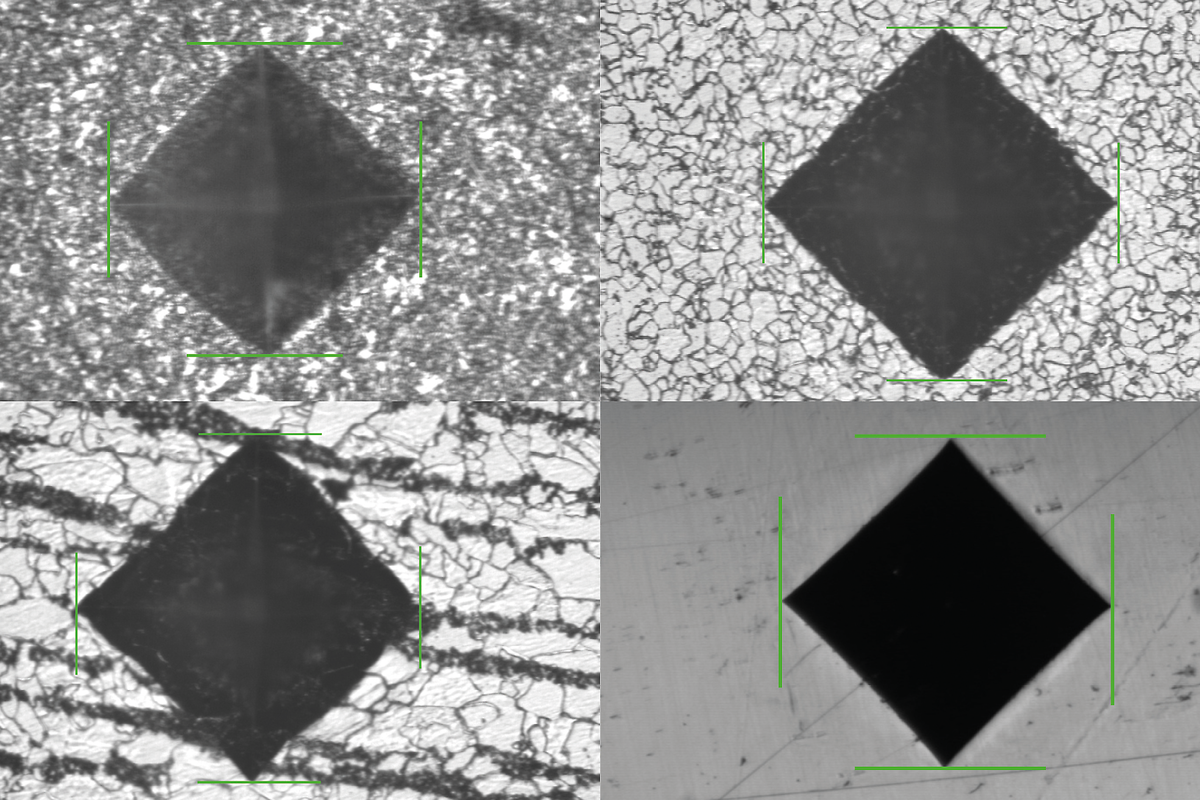

| Test method | Vickers, Knoop, Brinell, Rockwell (option) |

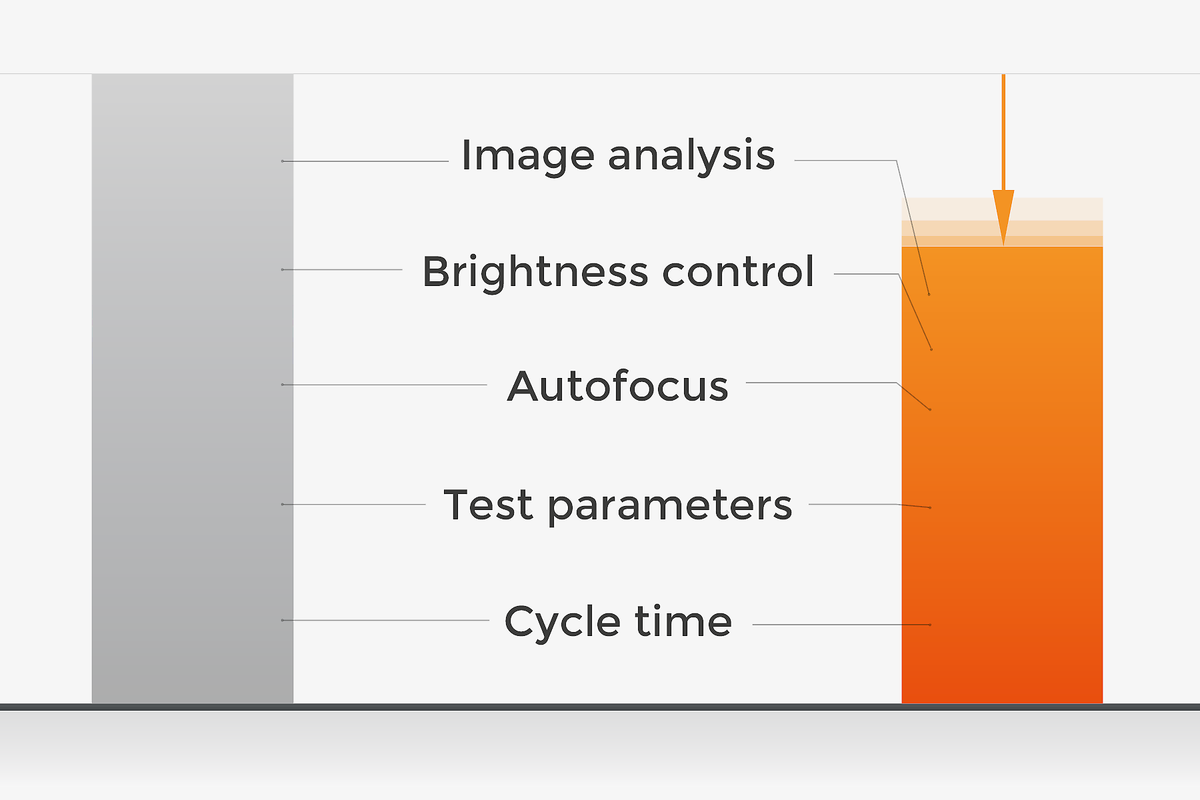

| Test sequence | Fully automated / electronic force application |

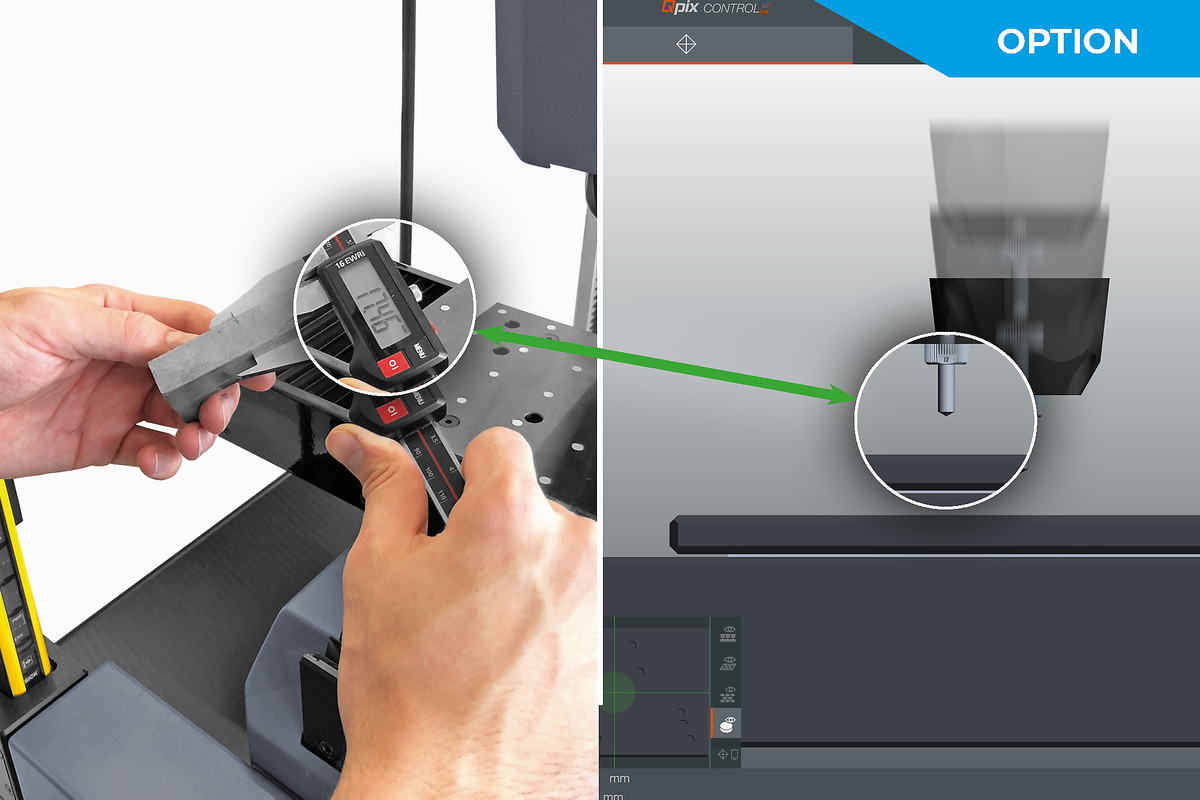

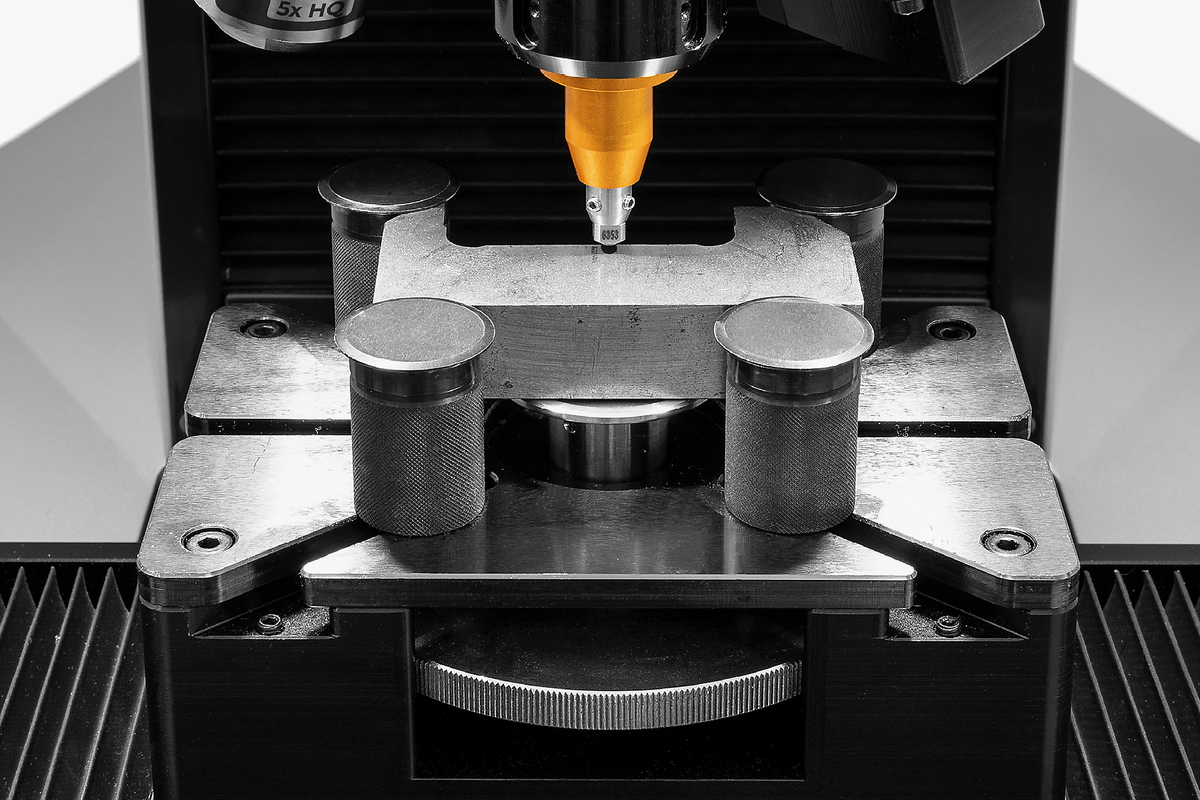

| Z-axis | Dynamic, automated (CAS-Technic) |

| Z-axis travelling distance | 150 mm (5.91“); Option: 260 mm (10.2“) |

| Throat depth | 170 mm (6.69“) |

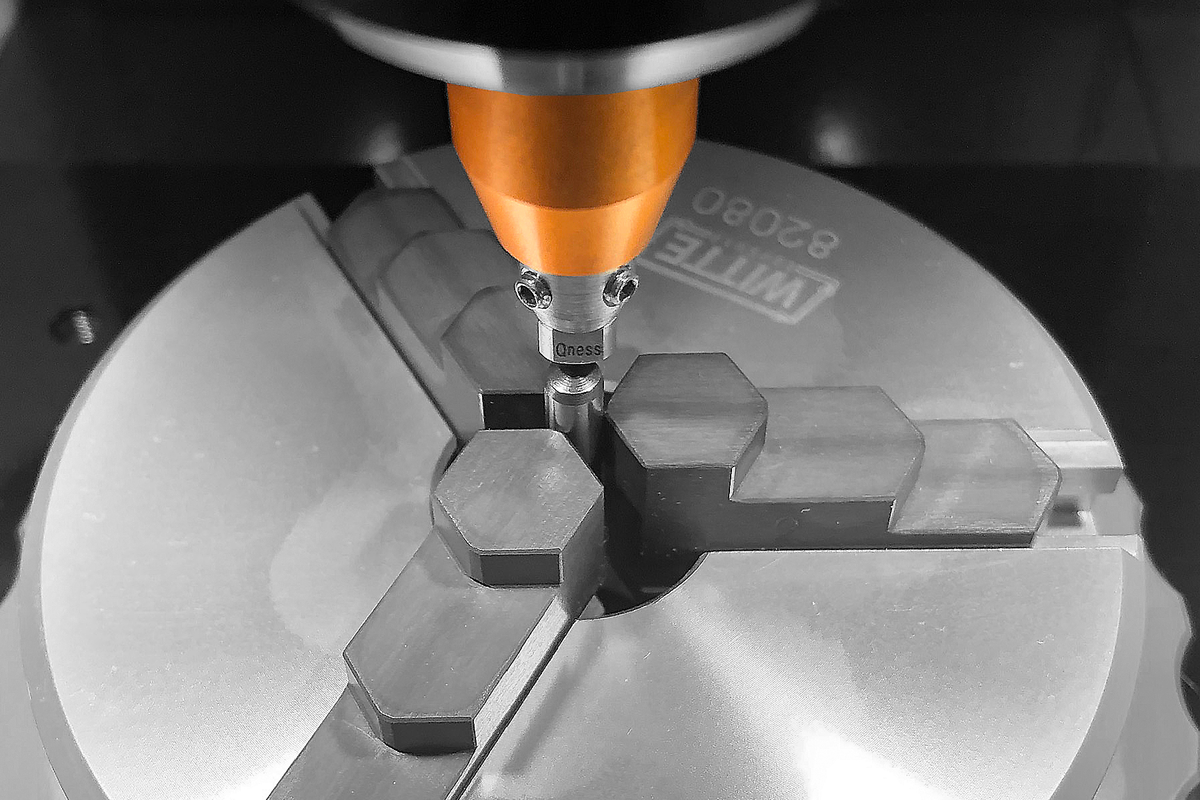

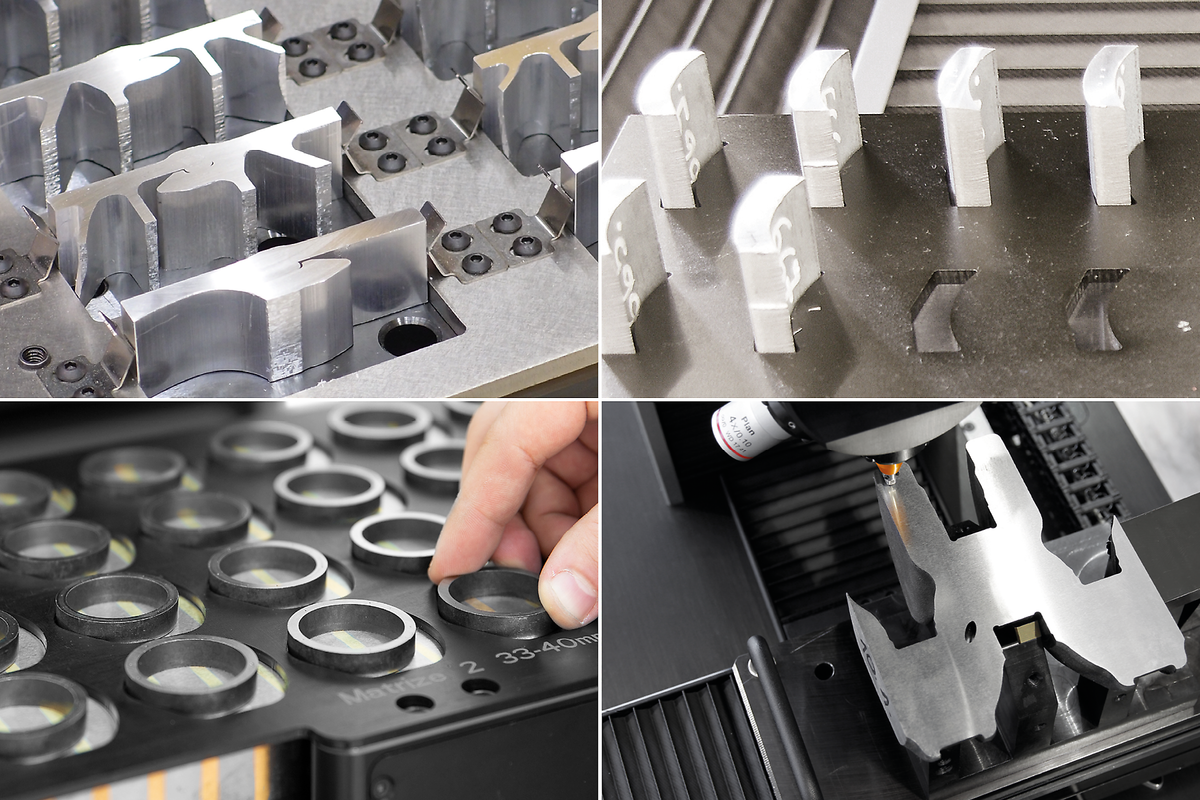

| Tool positions | 8-fold motorized tool changer max. 3 hardness testing modules, max. 7 lenses |

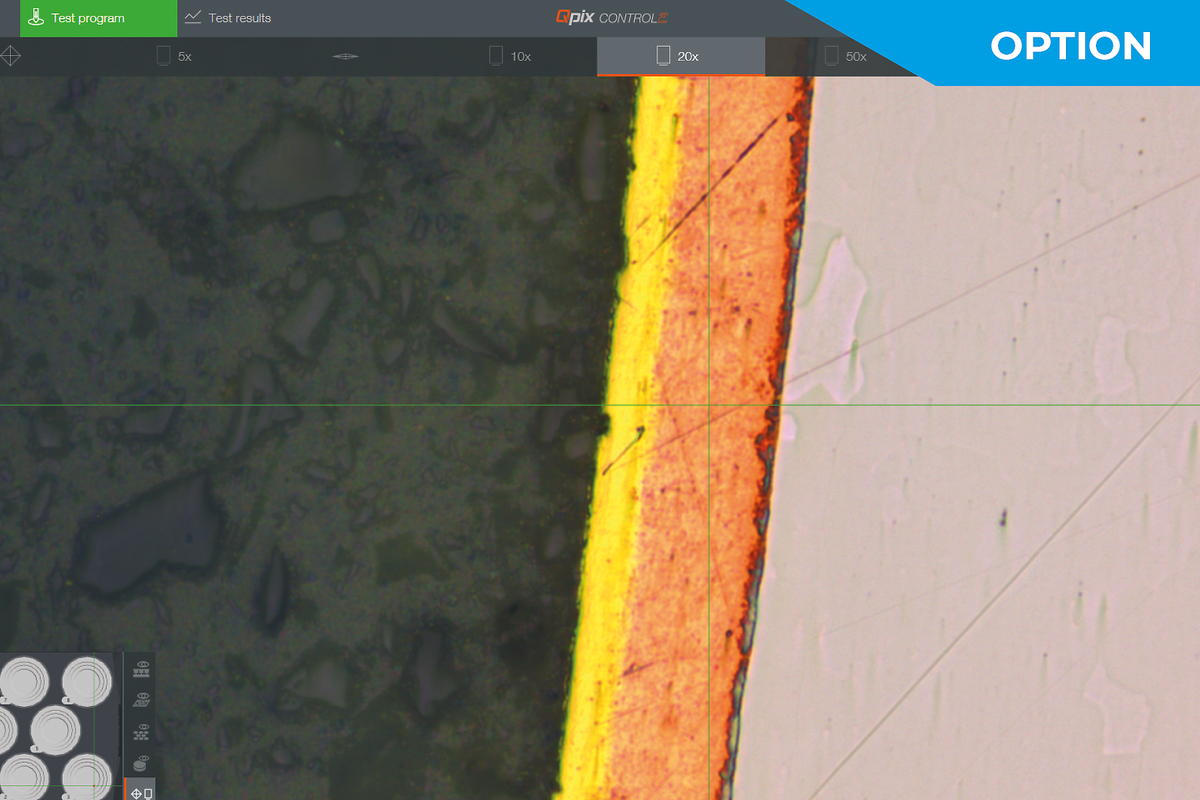

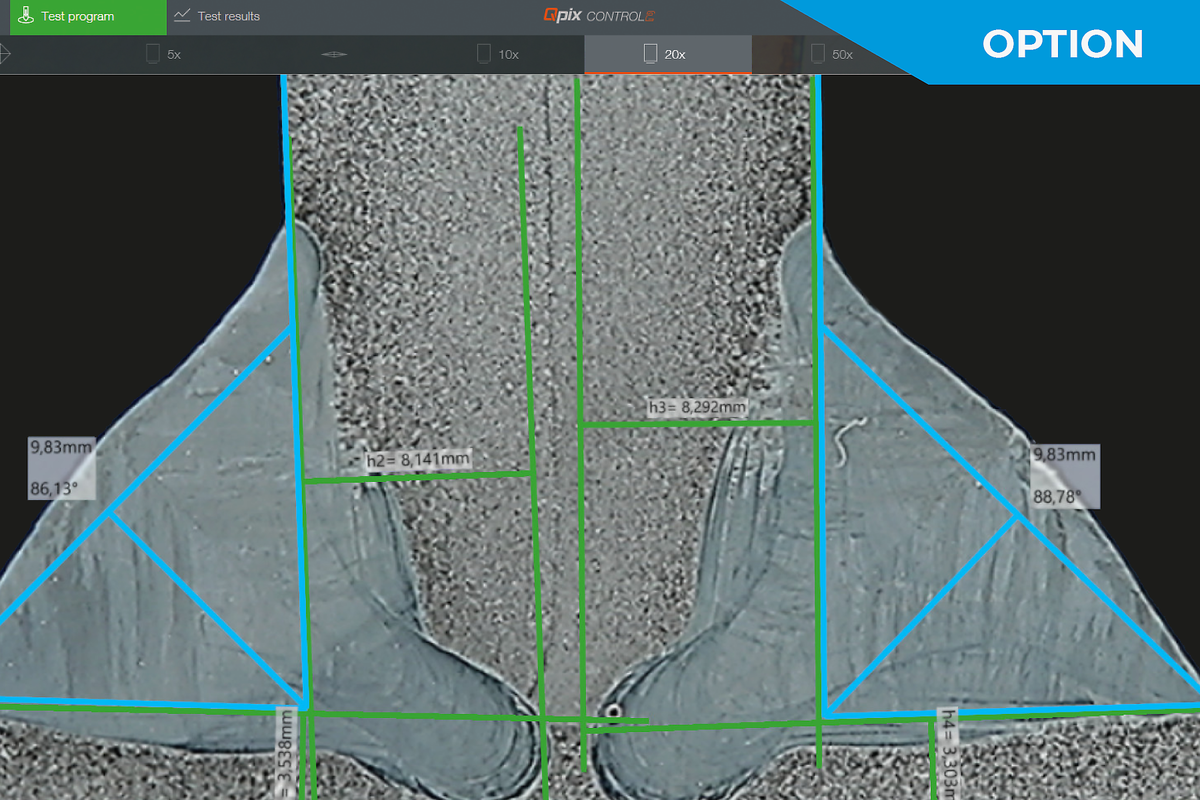

| Camera system | 5 Mpixel - CMOS color, USB3.0 |

| Optical system | Upright microscope with Koehler lighting |

| Aperture diaphragm | motorized |

| Lenses | XLED 2x, 2.5x, 5x, 10x, 20x, 50x, 100x |

| Lens types | Standard (Achromat) and High Quality (Semi-apochromat) for hardness testing and microscopy XLED for optimised Brinell hardness testing |

| Field of view (acc. to equipment) | 0.074x0.055 mm (100x) to 2.80x2.10 mm (XLED 2) |

| Sample image camera | 5 Mpixel - CMOS color, USB3.0 52 x 39 mm (2.05 x 1.54“) |

| Test anvil / XY cross slide | Automatic cross slide |

| Table size | 150 x 120 mm (5.91 x 4.72“); Option 300 x 120 mm (11.8 x 4.72“) |

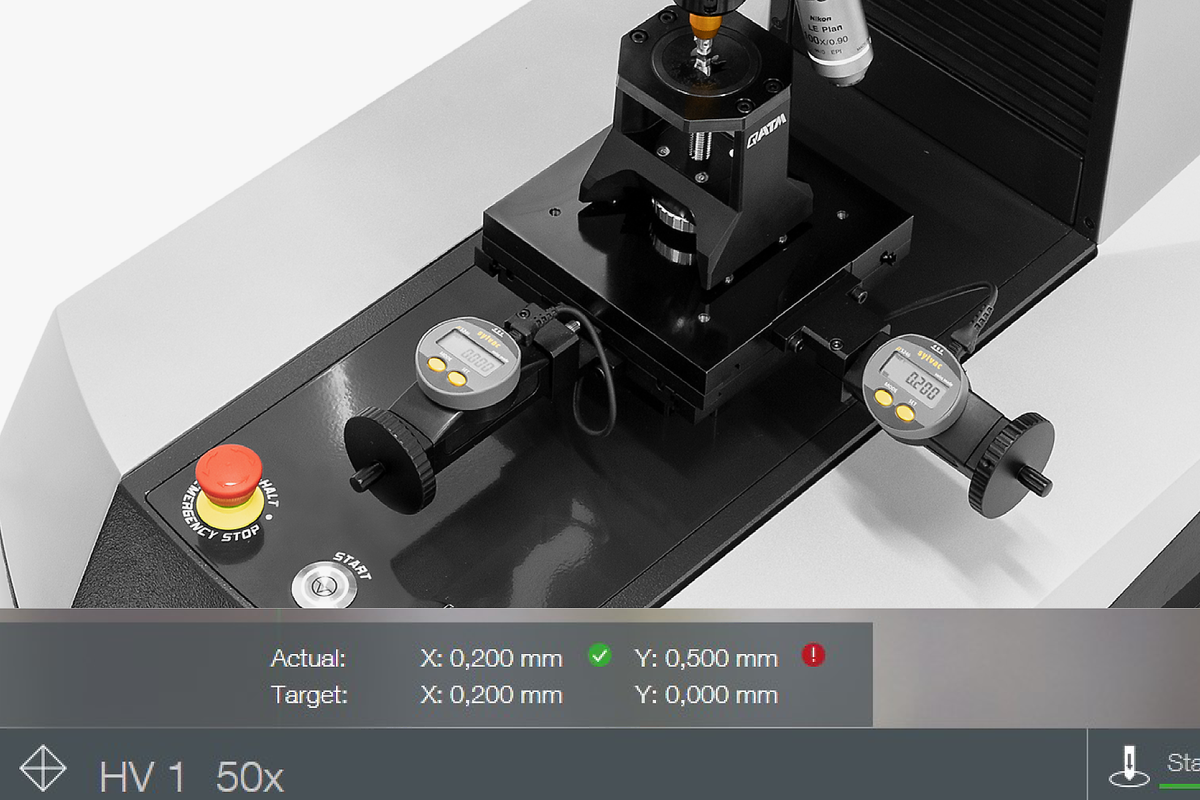

| Positioning accuracy | +/- 2 μm |

| Traverse path at cross slide | X 150, Y 150 mm (5.91 x 5.91“); Option: X 300 x Y 150 mm (11.8 x 5.91“) |

| Control elements | Emergency stop, Start button, Joystick X/Y/Z |

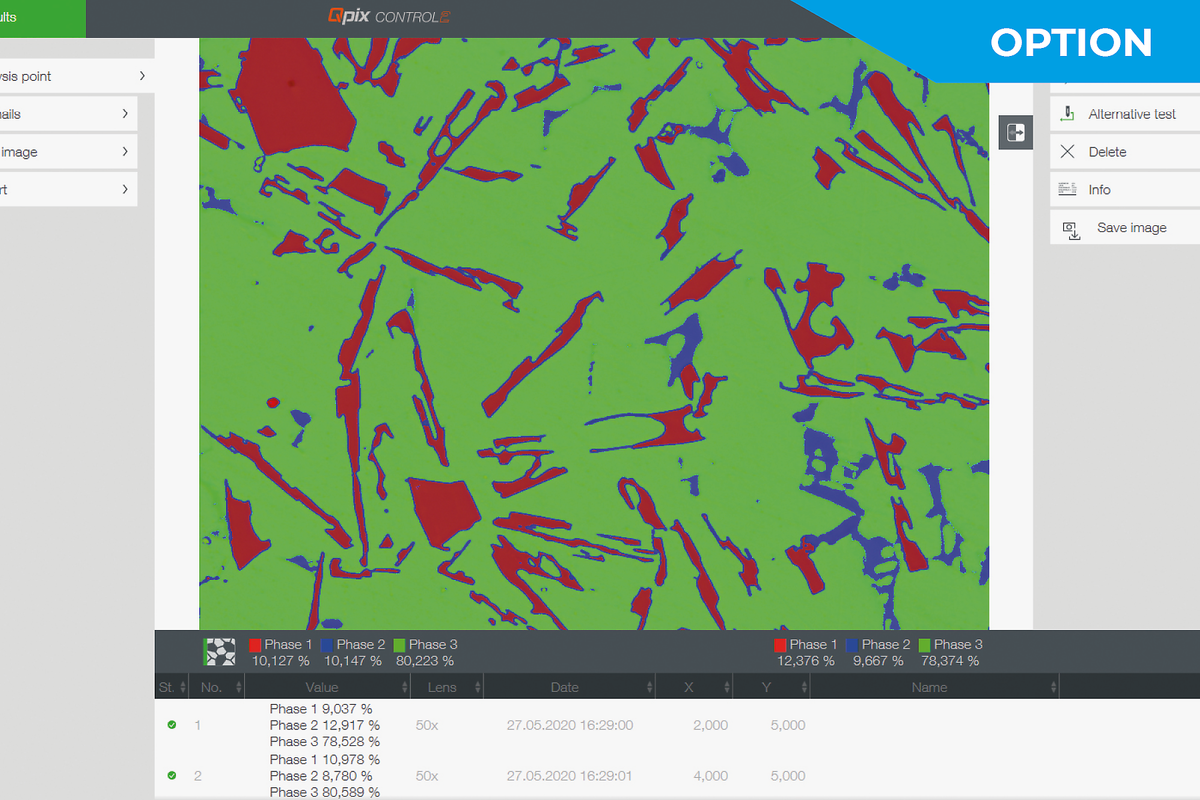

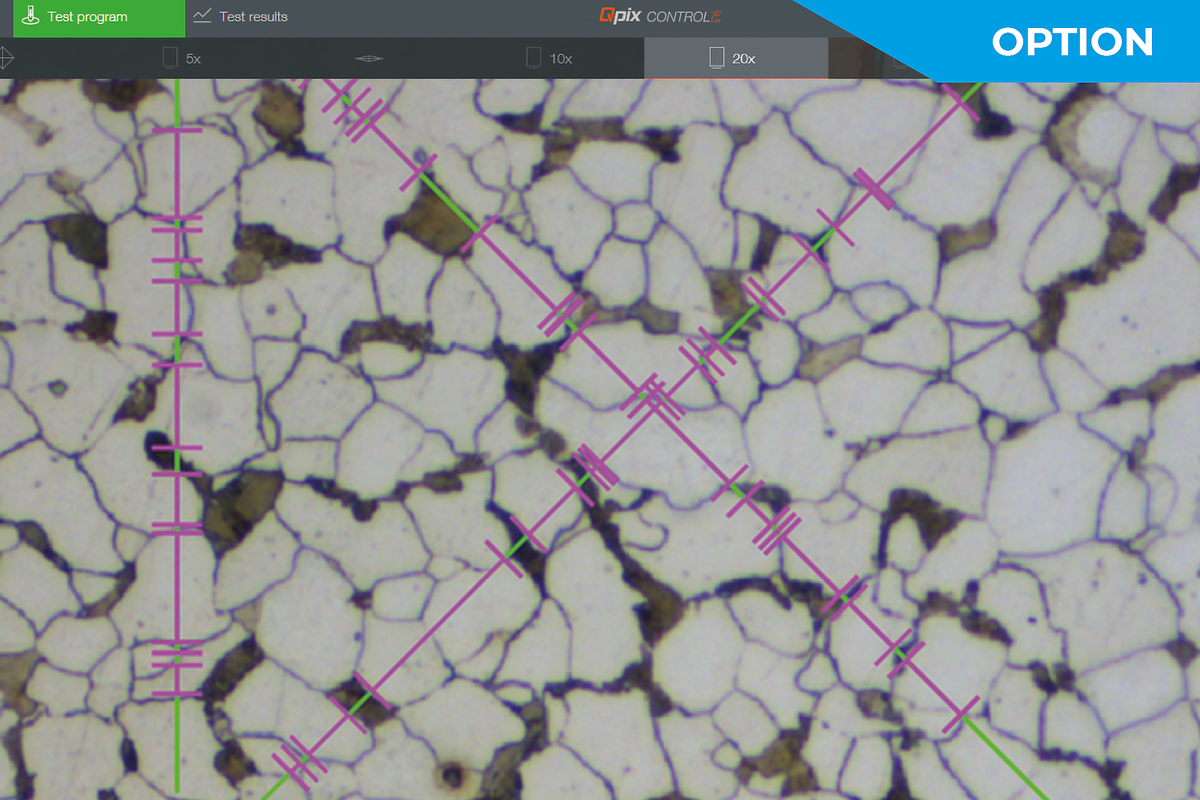

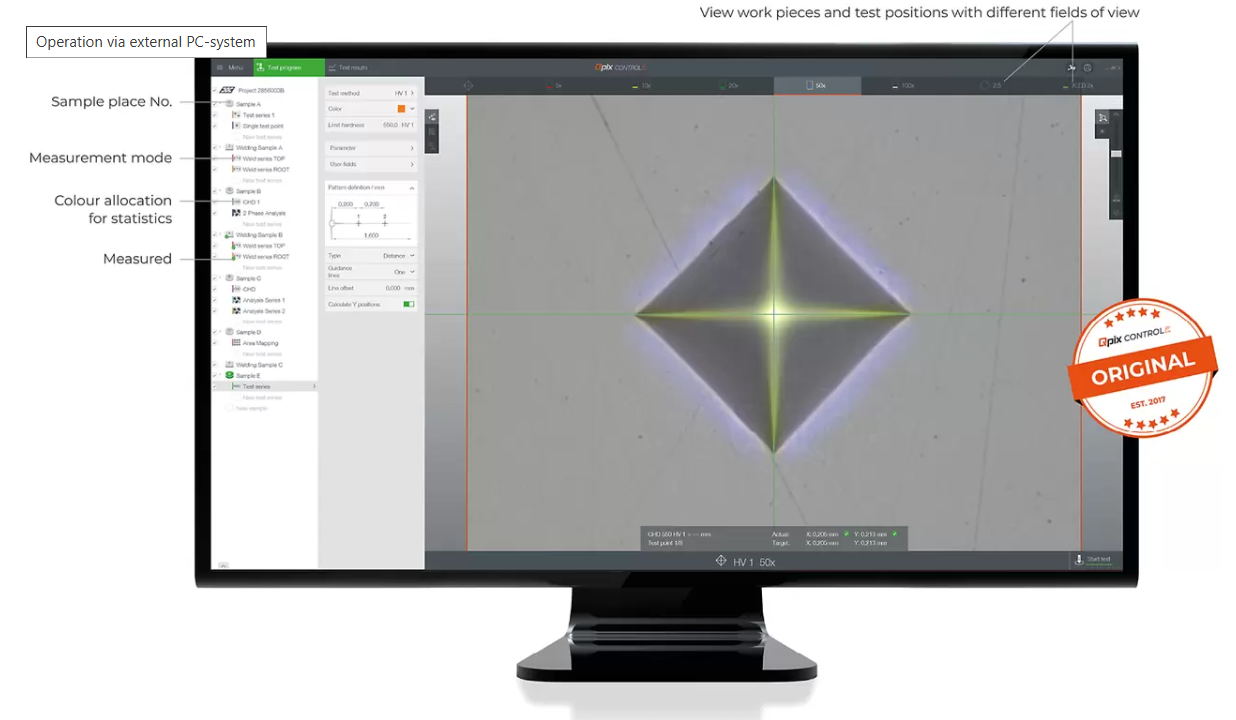

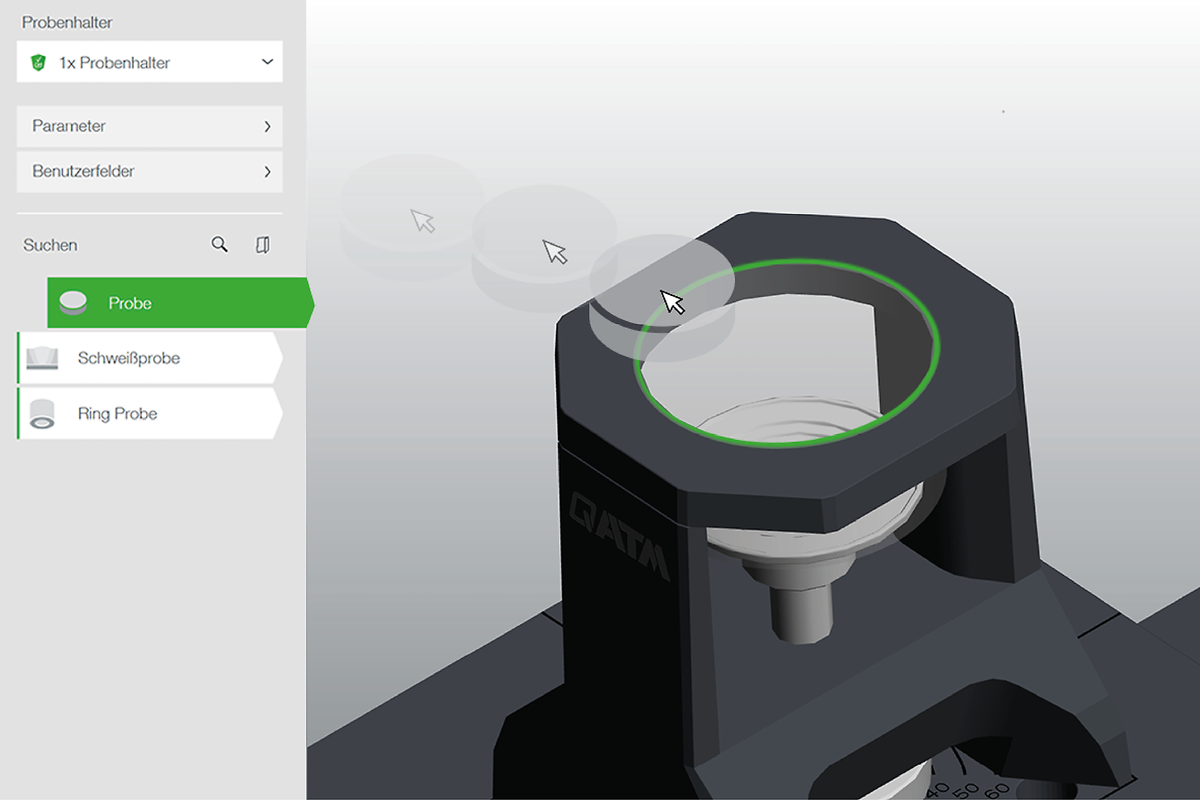

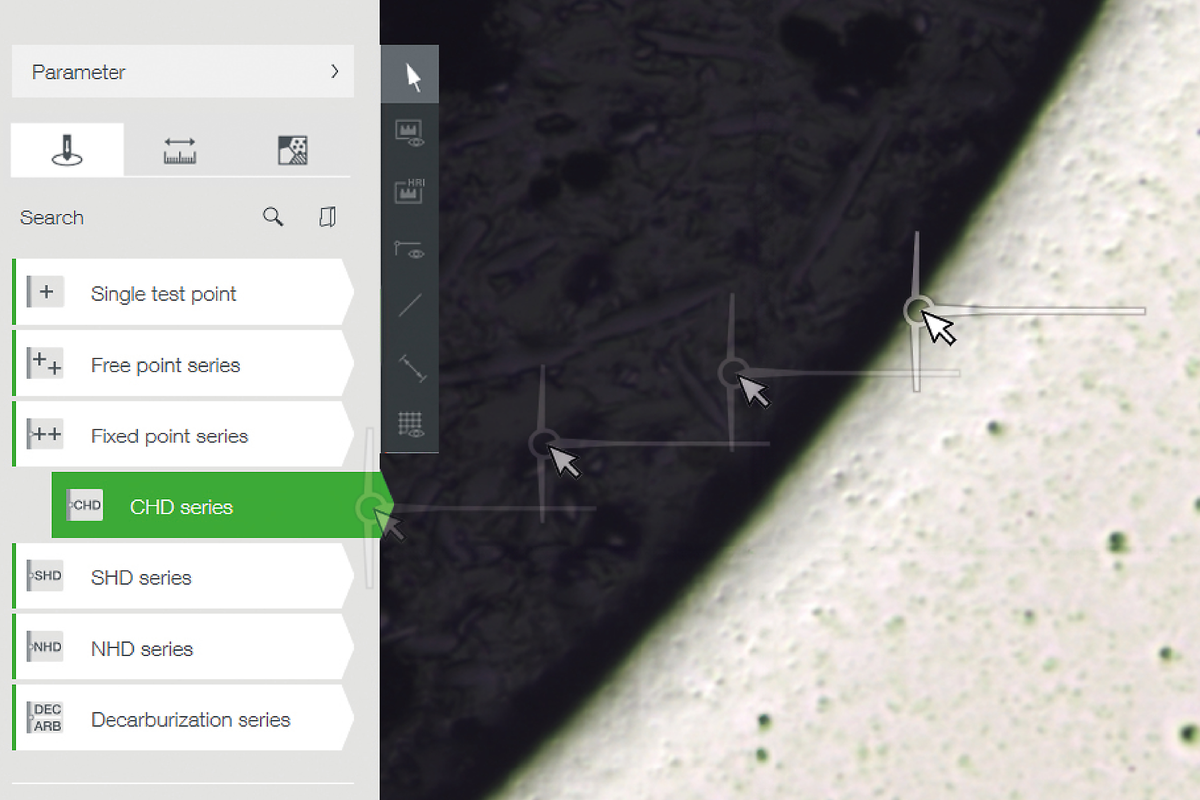

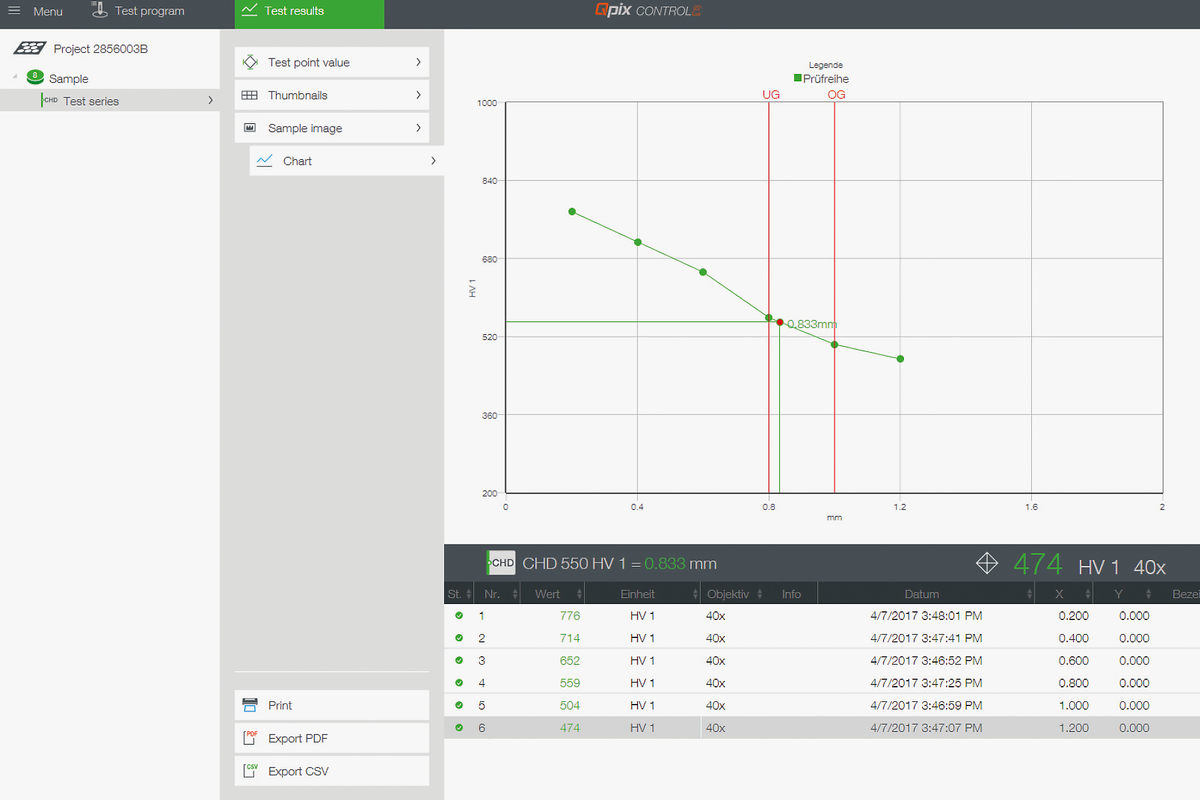

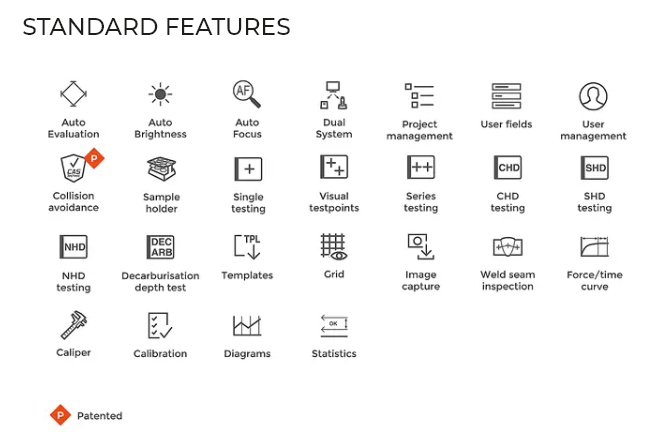

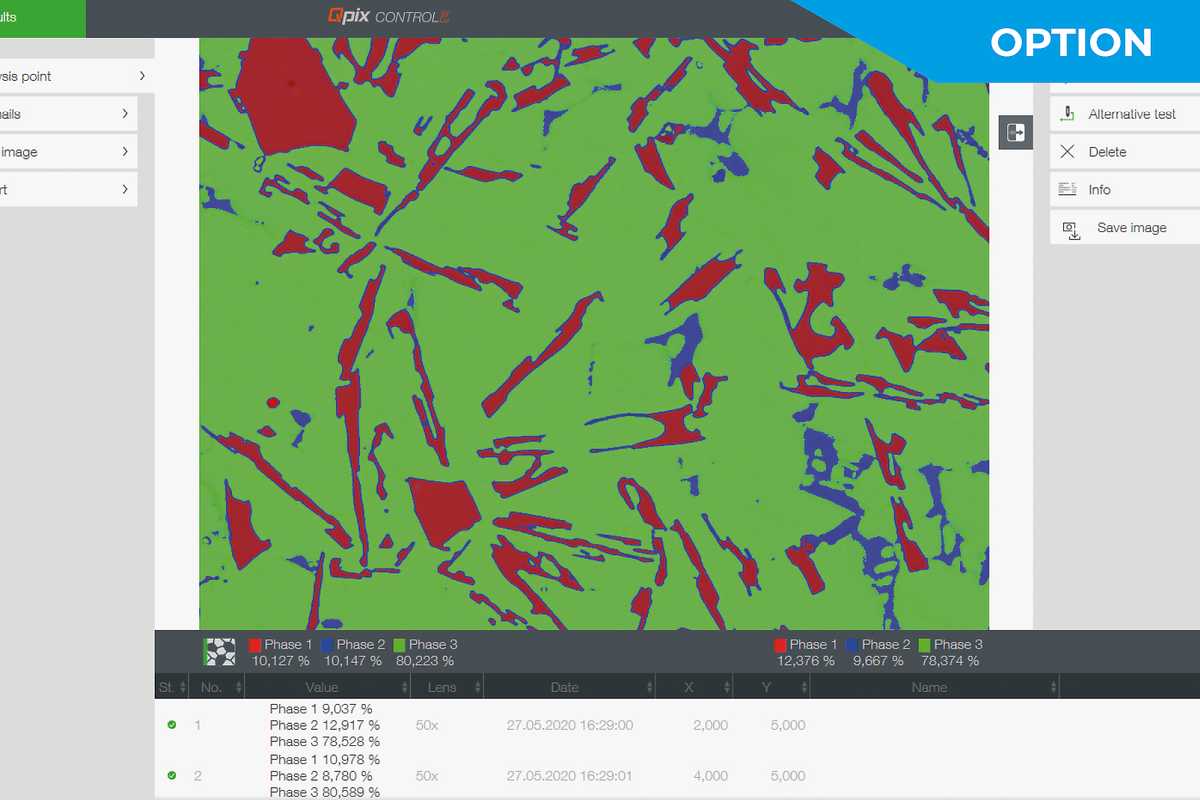

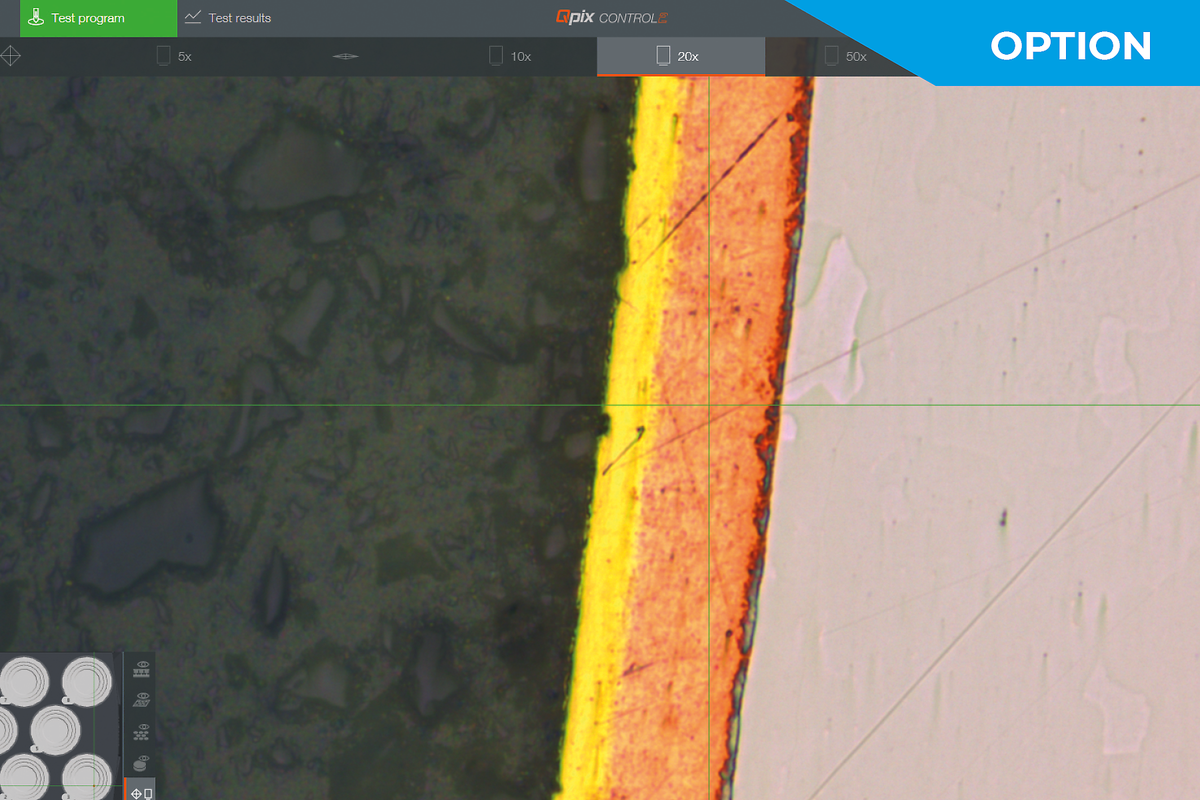

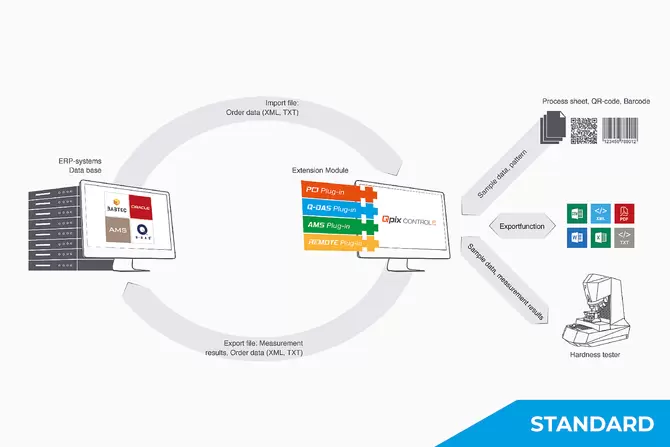

| Software | Qpix Control2 |

| Max. workpiece weight | 50 kg (110 lbs) |

| Weight of basic device | 60 kg (132.3 lbs) |

| Included basic equipment | Indenter Vickers ASTM + DAkkS; Lens 5x, 20x, 50x |

| Interfaces | 1 x USB 3.0 |

| Power supply | 100 – 240 V ~1/N/PE, 45-65 Hz |

Mikrotvrdoměry QNESS

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.