|

TECHNOLOGIE EXAKT - řezání tenkých výbrusů

Příprava vzorků s přesností na tisícinu

|

|

|

|

|

|

|

EXAKT diamond band saws are based on outstanding precision engineering combined with matchless process technology. Only this way it is possible to cut the most diverse materials and material combinations. Whether it is for research, quality management or damage analysis: With our technology you will get an immediate assessment of complex components and their structures without having to carry out additional grinding and polishing steps.

EXAKT cutting and grinding devices make it all possible. Versatile in use, all requirements can be met in daily laboratory use.

|

|

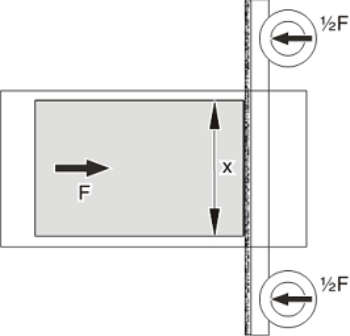

CONTACT LINE (CL)

The cutting technology named by us after Contact Line (CL) is the usual procedure for all band saws. Here, there is a line-like contact between cutting band and sample. This simple method is sufficient for a number of applications. However, in conparision to the contact point (CP) method, this method generates more friction due to the larger contact area between the cutting band and the sample. Higher feed forces are required for the cutting process and this results in higher thermal and mechanical stress applied to the sample. A lower surface quality and even structural damages can be the result. Furthermore, the cutting band will wear more quickly, too.

|

|

|

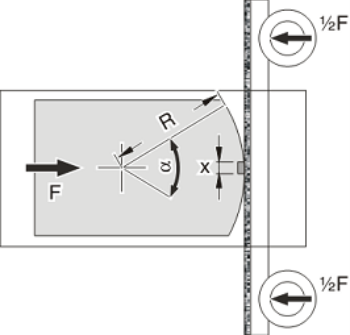

CONTACT POINT (CP)

In contrast, the cutting technology named by us after Contact Point (CP) only shows a point-like contact between cutting band and sample. This is achieved by a especially designed, servo driven clamping fixture which is oscillating the sample in a rotary movement. Osciallating speed as well as the swing can be adjusted. This technology guarantess higher cutting speed, a superior quality of the cutted surface and less wear of the cutting band.

|

|

|

EXAKT DIAMOND BAND SAWS PATHOLOGY - HISTOLOGY - ANATOMY

|

|

Do you have to deal with the following problems in the sample preparation:

- High risk of injury when using butcher saws with toothed cutting band, especially if accidentally cutting an implant or a screw.

- High security measures required and restrictions on the selection of operators when using butcher saws.

- Severe damages to the sample (artifacts, micro-fractures, breakouts, uneven surfaces)

- Specimen cannot be cut small enough

- Great loss of material

- As a result, a lot of work and time in preparing the sample after the cut

All these problems can be eliminated with the EXAKT diamond band saws!

Whether soft tissue, bone, teeth or implants (metal and ceramic), all samples can be cut quickly, accurately and safely directly in the lab.

Our diamond band saws do not cut but grind very precisely. Thus, even smallest cuts of only 1-2 mm thickness can be produced free hand - with maximum working safety. This means that our diamond band saws EXAKT 312 and 302 can be easily used by any user. Directly in the lab and with a surface quality of the cut surface that no other method can provide. An initial assessment of the cut can generally be made right away.

Your advantages at a glance:

- No direct cutting risk for the operator

- Cuts each sample quickly, accurately and safely

- Produce even smallest cuts of 1-2 mm - free hand

- Assessment of the sample usually possible without reworking

- Can be used directly in your laboratory

- High standard for safety and hygiene

- Easy operation and cleaning

Optimize your process of sample preparation and shorten process times, especially for the decalcification of specimen.

|

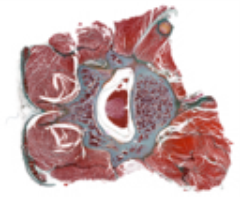

Querschnitt Schafskopf

Queschnitt Fuß

|

|

EXAKT THIN SECTION CUTTING TECHNOLOGY PERFECT SAMPLE PREPARATION

|

In medicine, the high-precision EXAKT thin section cutting system is used for the preparation of histological preparations, so-called thin sections, with a thickness down to 10 µm. Bone samples need not be decalcified for this. Thus they retain their cell information and morphology. The method of Thin Section Cutting Technology is especially important in the study of interfaces of implant/bone, bone/cartilage etc. since the interfaces can be prepared while preserving the structure and used directly for light microscopy techniques.

Among other fields, the system is used in the research and development of implants, stents, cardiac catheters, in oral pathology, dentistry, orthopedics, veterinary medicine or immunohistochemistry. It was developed in collaboration with Prof. Donath, Institute for Pathology at the University of Hamburg in 1987 and since then has proven itself to be unparalleled.

|

Sardelle Kopf /

Movat Pentachrom

Ratte-Wirbelsäule /

Masson Goldner Lichtgrün

Zahn Implantat

|

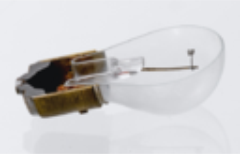

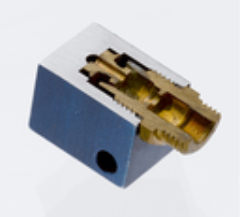

EXAKT CUTTING & GRINDING SYSTEMS FOR QUALITY CONTROL AND R&D

|

Whether it’s for research, quality management of industrial production or damage analysis:

Comprehensive and detailed knowledge of the materials and production processes being used, as well as their mutual interdependencies, are required for new materials and composites, complex production processes and ever-increasing quality and safety demands. Take advantage of the quality of our abrasive grinding units to get an immediate assessment of complex components and their structures without having to carry out additional grinding and polishing steps. To meet this requirement, it is necessary to make informative cross cuts or thin sections for visual or reflected-light microscopic examination. Over time, the added requirement of additional transmitted-light microscopic examination of thin sections down to 10 μm in size is becoming more and more common.

EXAKT Cutting and Griding devices make it all possible. Versatile in use, all of these requirements can be met with just a few pieces of equipment in daily laboratory use.

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but rather cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely and the sample surface quality is left unimpaired. EXAKT Cutting and Grinding Technology enables you to approach sample examination in ways which simply weren’t possible for your application until now.

Long service life, reliability and minimal service expenditure also contribute considerably to the economical use of our systems.

|

Glühbirne / bulb

Objektiv / Lense

Ventil / Valve

Kabel / Wires

|