Popis

FRETTING TESTERY - řada FFT

Zkoušky koroze třením

- Koroze třením

- Vysokofrekvenční korozní tření

- Tření a opotřebení

|

Tester HFRRHigh Frequency Reciprocating RigNext Generation HFRR lubricity tester with real-time force and stroke control, piezo sensors, and wide temperature range. |

POPIS PŘÍSTROJE:

- Real-time down force control

- 1 to 200 Hz, 10 µm to 2.8 mm

- Real time friction with piezo load sensors

- Room to 180 °C (cooling and up to 400°C options available)

- Load Range up to 20N (More ranges available)

Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no dead weights). Combined with piezo sensors to measure real-time friction. The ease of use, flexure based design makes this tester highly reliable and repeatable. Test collected samples from field or for research purpose. The FFT-M provides a fully automated and computer controlled test. Setup is easy to calibrate and comes with standard oil and samples. Each tester conforms to several ASTM standards including the most widely used ASTM D6079. In addition to standard testing, the wide stroke, frequency, and load range allows development of new custom test methods. Perfect for understanding next generation fuel additives.

a fretting machine like no other

Test the surface damage that occurs between two contacting surfaces. Analyze two-body abrasion, adhesion, and/or fretting fatigue wear.

|

|

Without the friction of rolling or bearing, the magnetic flexure based design provides the control required for the most sensitive of tests. The unique controller adjusts to friction changes to maintain the stroke control in real-time. The fretting tester comes with high frequency piezo sensors to measure real-time friction. Ultra low noise amplifiers aids in detection of minute changes in friction with ease. Sensors such as acoustic emission to detect onset of cracks, and ECR to measure surface resistance changes to gain more insight on the material interface.

Customizable liquid and sample holders for standard and non standard tests. |

Data and Analysis

FFT series fretting wear testing instruments are optimize for friction, wear, and fretting fatigue tests at small amplitude and high frequency.

|

|

|

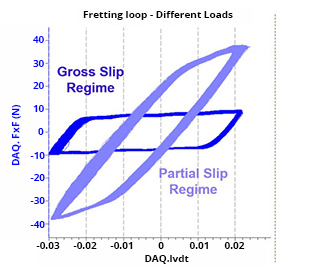

Fretting Loops |

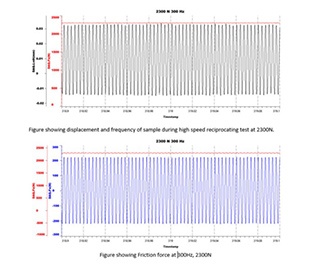

Real Time Friction Curves at 300 Hz, 3000 N |

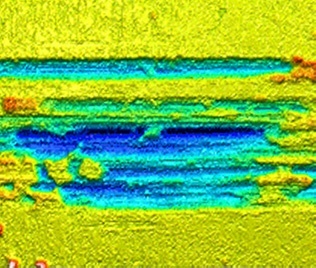

Fretting Failure Marks |

|

Rigid design with accurate real-time friction force allows the measure of fretting loops at different temperatures, and loads. |

The graph shows real-time friction data at 300 Hz, 2300 N test on dry material fretting test. |

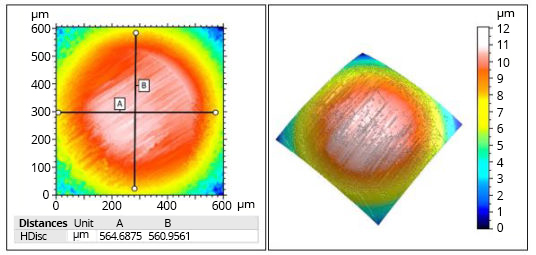

Rtec 3D profilometer allows to create 3D images of surfaces with ease. |

ASTM Tests and More

|

Our lubricity tester, the FFT-M, performs friction and wear analysis on petroleum products.

|

|

|

Typical Test Analysis

- Evaluate diesel fuel lubricity

- 1mm 50 Hz, 200 gm force

- 6 mm diameter ball, disc 10 mm diameter x 3 mm thick disc

- Humidity control and monitoring

- 70°C temperature

- Wear scar and friction analysis

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB)

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB) BROŽURA FFT_M (1.2 MB)

BROŽURA FFT_M (1.2 MB) BROŽURA ŘADA FFT (917.4 kB)

BROŽURA ŘADA FFT (917.4 kB)

VIDEA:

| Hmotnost | 0.1 kg |

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.